In 1904, Andries Gaastra opened a shop selling clocks, watches, sewing machines, and small farm machinery equipment. Within two years, he had also started selling bicycles manufactured by the German Presto company, and quickly dropped the other products to concentrate on cycles, which were becoming widely popular.

He soon began making his own bicycles and selling them under his own Batafus and Batavus names, listing the two brands side by side. By 1917, Andries had taken over a large bicycle factory. He continued using the two brands until the Batafus badge was dropped in 1923, and hasn't been used since, though the Batavus Company still holds the patent on it.

The 1930s proved difficult as much of Europe became locked in the great economic recession, but Batavus continued growing by diversifying to include carrier tricycles, motor cycles, and ice skates.

In 1936 Batavus marketed its first motorised cycles for both men and women, however because the Netherlands had no laws on the use of such vehicles, it was deemed necessary by the authorities to require regular rider testing for a driver’s licence, which was the main reason why the cyclemotors weren’t a commercial success in the thirties.

World War II saw the temporary shutdown of the factory, but business resumed when the war ended in 1945 and demand for bicycles increased, so the company invested in a new factory with modern assembly lines, which brought it to the forefront of cycle manufacturing. With the uptake of fitting attachment engines to bicycles, Batavus started manufacturing specific Hulpmotor frames to take particular popular makes of cyclemotor engines like Mosquito and Itom Tourist, before presenting its first moped in 1951 as the Ilo F-48 powered Bilonet.

By 1954, the company’s assorted factories produced a variety of machines, but in 1956, 52 years after Gaastra had opened his shop, a new factory opened in the industrial park at Heerenveen. It had an area of 6,000m² and the workforce had grown to 300. After the new premises opened the company continued primarily to be a bicycle manufacturer, though moped sales in Holland were also booming, and Batavus produced many different Bilonet commuter models and Transport carrier mopeds, before introducing further Toer and Sport models in the later mid-1950s. With a change to regulations, separate dual-saddle CombiSport models became single dual-seat Super Sport and CombiSport models from 1959, and the range extended further with Conforte versions, and the most popular Whippet Sports with high-level twin exhausts from the single cylinder motor.

In 1966 Batavus introduced its first Batavette automatic mopeds with a rigid frame and options of rigid or telescopic forks; this was powered by the new Dutch NV Anker Motoren Maatschappij engine manufactured in Rotterdam at the former Berini factory.

Anker was part of a major group that held interests in shipping, coal, bricks, oil and electrical products, which bought into mopeds and engine manufacture when Berini went bankrupt in 1964 and was purchased by the Laura state mining group Anker Kolen Maatschappij. Laura was originally the coal mine named after his wife by its founder Anton Wackers, with drilling of the first (Wihelmina) shaft in 1901, and followed by a second (Hendrik) shaft in 1902 (which were presumably named after his children). The Berini brand was successfully returned to moped market sales again and the manufacturing division was structured into three branches: Clinton–Laura (stationary engines), Boatmaster–Laura (outboard motors), and Anker–Laura (moped engines).

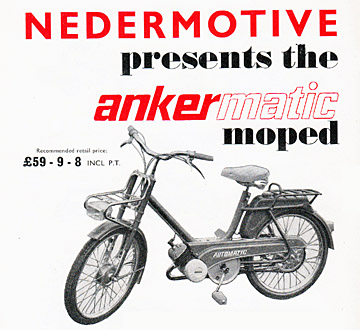

The first Anker engines to find their way to the UK were in the Dutch Gazelle-manufactured Ankermatic mopeds imported by Nedermotive Agencies, 37 Holland Mews, Hove, Brighton.

In 1967, Anker divested its interests in the Berini moped brand to Gazelle, who then also sold identical Ankermatic models under the Berini badge, as well as its own Gazelle name.

However, the mining group retained the Anker engine manufacturing and re-established engine building in 1967 with Anker–Laura as the new brand name of Laura Motoren at Eygelshoven in Limburg. The new factory was set up by the Laura & Vereniging coal mines as replacement employment after the Laura mine ceased production in 1968, followed by the Julia mine closure in 1974.

UK imports of the initial Ankermatic model finished in March 1968, but briefly resumed again by a seemingly new importer as SS Motor Cycles, Anker House, 46–50 Dean Road, Bitterne, Southampton, with the Ankermatic MkII version from July to September 1969.

Further Anker powered Batavus Batavette versions followed as the V1, V Mini 1, and VA2 with rear suspension in 1968, and the V Mini 2 in 1969.

In 1969, Batavus acquired the bicycle and motor cycle production of the Dutch Magneet company, and the following year took over three other three-wheeler factories in Germany. Although sales of motorised two-wheelers fluctuated with model and style changes, there was steady growth year-on-year.

Elements of the original Anker engine with its round-finned cylinder and head were modified in Limburg and incorporated into the later type M-48 motor with square-finned cylinder and head for 1970.

In 1970, Batavus joined the Dutch Laura group, which included Laura Motoren, and Anker–Laura engines would be fitted into a new range of Batavus designed mopeds, excepting the top-of-the range Sachs-powered MK4S sports model.

The Laura Motoren factory built and supplied engines to Batavus, Gazelle & Berini, BSA for the Ariel-3, Tomos, Solifer, and Solex for the Ténor model. There was also an outboard motor in their model package under the name Laura–Boatmaster.

Anker Laura motor specifications.

M 48-01: 40km/h

M 48-02: 50km/h (UK) rated 2.4bhp @ 5,000rpm

M 48-03: 30km/h (CH: Switzerland)

M 48-04: 30km/h (DK: Denmark)

M 48-04: 30km/h (S: Sweden)

M 48-05: 25km/h

M 48-08: 45km/h

UK market versions were supplied in 02 specification, so we probably want to consider ourselves lucky—we had the fast ones!

We don’t have much in the way of further details as to how Euro market motors were performance limited, but smaller bore carburetters (typically 8mm) are one likely means, and European market models were also fitted with aluminium head gaskets (UK market models did not have any head gasket, so the compression ratio would have been higher).

The lower performance rated machines also seemed to have run lower drive ratios. Dutch market belt flywheels typically have 12-tooth front sprockets, whereas UK market flywheels were fitted with 13 teeth.

An Encarwi S22 of 12mm bore supplied the fuel. Induction wasn’t by the more usual piston ported control, but reed-valve directly into the bottom of the crankcase, which means the carburetter sits underneath the motor.

Since a reed-valve closes as soon as the piston comes down, it retains a full charge of induction gas to deliver up the transfer ports to the combustion cylinder, whereas piston-ported engines tend to lose a proportion of this charge as ‘blowback’ to the carburetter, particularly at lower revs. The ‘blowback’ effect on piston-ported motors tends to be negated toward increased revs, so reed-valves offer little difference to the top speed. Their advantage is apparent in low speed torque, generally making a reed motor more effective at acceleration, hill climbing, and into a head wind.

In the early 1970s, bicycle demand continued to increase, prompting expansion of the Batavus Heerenveen factory to 25,000 square metres.

1972 production records indicated 250,000 bicycles and 60,000 mopeds built in the year, of which 60,000 bicycles and 27,000 mopeds went for export. Sales were strong in West Germany and Switzerland, while Iran, Israel, Belgium, and Greece were also considered important markets. In Turkey, Batavus mopeds began to be manufactured under licence in 1972.

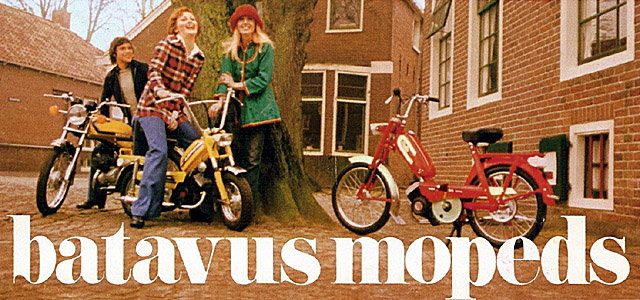

Though Batavus was a long established manufacturer just across the North Sea in the Netherlands, the brand only started exports to the UK from July 1973. First imports began with the setting up of Harglo by two former BSA/Triumph executives, Wilf Harrison and Peter Glover, who imported and distributed Batavus mopeds in the UK and Ireland, starting with Go-Go ‘V’ & ‘VA’ models.

Four other new machines were added to the UK market imported list in 1974, comprising three further Anker–Laura engined models, as the Compact (small-wheeled mini-bike), Bronco (trail), and HS50 Sports models from January 1974, and the MK4S 4-speed Sachs-powered sports moped from August 1974.

The early Go-Go V was a rigid frame machine, but discontinued manufacture at Batavus shortly after the introduction of the Go-Go VA sprung-frame version, so UK imports of the V model ceased in April 1975. By this time the company had a reputation for well-built machines, which, while not the cheapest or particularly fast, looked smart, and proved simple and reliable.

A new Starglo model was added to the import list from October 1976, and Harglo showed their seven-model range at the Earls Court Motor Cycle Show.

The top-of-the-range MK4S specification, with motor cycle styling and the Sachs four-speed motor, included an electronic tachometer, battery-operated indicators, and heavy-duty suspension front and rear. This model, which has the overall dimensions of a full-sized motor cycle was the biggest machine sold by Batavus.

In 1977, Batavus made more bicycles and mopeds than any other company in the Netherlands, and was the biggest Dutch exporter of machines, with 55% of production going outside the country.

To accommodate a developing interest for fuel-efficient transport in the USA during the 1970s, Batavus set up its US market headquarters in Atlanta, GA.

UK imports of the Go-Go VA discontinued in March 1978, and its position in the model range was wholly replaced by the Starglo. In September 1978 a dual-seat Starglo-2 model was introduced, though this seems to have been fairly unsuccessful since it became re-listed as ‘imported to special order only’ after April 1979.

Our purple Go-Go VA would seem to have been among the last of its class, being V-registered in late 1978.

With front and rear suspension, the single-speed Go-Go would seem to be aimed at the middle ground of basic commuter mopeds, and appears a fairly compact machine due to the 16-inch wheels giving a short 64-inch overall length and just a 43-inch wheelbase.

Operation is simple, just turn on the fuel tap at the bottom left of the tank, then the manual says ‘with a cold engine, pedal a few yards and then pull in the start lever. As soon as the engine starts, release the start lever and twist the throttle. Keep the choke lever pressed in during the first 20–30 seconds.’

So we give that a go with the ‘flying’ type start, and yes, the Anker–Laura M48 engine fires right away, and seems happy to run without choke almost immediately. The reed-valve system often seems to offer easier starting than some traditional piston-ported engines, which is always a benefit.

Twist open the throttle and Go-Go pulls away smoothly and easily under its own effort, and without any request for pedal assistance. The engine delivers unfaltering acceleration right from the off, though the better top speeds are unlikely to be attained until the engine has thoroughly warmed up, so we cruise around the first part of our test course to get the general feel of the bike.

Go-Go feels well together along bumpy surfaces, handles tidily enough on corners though seems a little cramped in its riding position as the saddle feels somewhat too close to the handlebars with only a limited adjustment for height, and rises at an angle that takes it towards the handlebars as it goes up.

The 60mph VDO speedometer tended to wave its needle over a greater range as the bike went faster, so failed to give any useful indication—we had to rely on our pacer. We cruised around the outward leg of our test course at a comfortable 25mph to warm the motor thoroughly, then raised the pace along the first straight of the return leg to clock 32mph along the flat with rider sitting upright.

At this point we should say that the engine in this bike had some modifications while it was in the workshops being rebuilt from a decrepit ruin; it was given a 1.5mm transfer porting lift with a 20% increase in vertical height of the exhaust port for better scavenging at revs, and a compression ratio increase up to 9:1. The downhill run was paced at 36mph, at which the motor was revving fairly hard, following which, the uphill climb was confidently despatched with the bike only dropping back to 25mph before cresting the rise.

Reed-valve motors often show strongly against hills anyway, but this performance was probably further helped by the compression ratio increase.

Catching a following breeze along the return flat in a prone position, our pacer clocked a peak of 34mph.

The tuned motor handled the higher revs smoothly and capably, which generally would be difficult to achieve on a ‘stock’ M-48 motor since they are commonly ‘held back’ by four-stroking in the upper rev range due to the restricted porting checking them back to the maximum design speed of 30mph.

The Bronco was de-listed in January 1979, and the Pronto model added in April. The HS50 Sports was discontinued in April 1981, and replaced by a new Mondial model with variable transmission.

Our featured Starglo was UK X-registered in 1982 and, though it looks fairly similar to its forerunner and has basically the same running gear, there are a number of different features from the earlier Go-Go model. The rear frame, swing-arm, and carrier arrangement is changed, and so is the seat mounting. Matching mudguards are aluminised steel instead of painted steel at the rear and stainless steel at the front. The exhaust pipe is a changed form. The side panels and fuel tank are modified and a plastic moulded tool tray is located in the forward space of the rear carrier, so that when the parcel clip on the rack springs down, it holds the lid closed.

It’s probably worth pointing out before we actually start, that despite having had some cleaning up and service work to the cycle components (new front inner tube, rear wheel bearings + new cup, and HMP chaingrease treatment), otherwise this machine is completely untried because it’s been unused since its last tax disc expired in July 1990! Yep, 30 years in the back of a shed, and we’re hoping it’s going to go for us…

The fuel tank has been cleaned out, with the seal replaced on its original tap, and a new fuel line.

All operational and control features are the same as the Go-Go, though the fuel tap positions are only indicated on the tank as Dutch hieroglyphs printed on faded vinyl stickers, which are probably nothing that even the most skilled archaeologist could interpret.

After a little experimentation with the fuel line detached, we establish the middle position is off, with on and reserve position to either side. Both positions work with the amount of fuel in the tank, so it doesn’t really matter which-is-which to us for our brief purpose of test running the bike.

Going with the ‘kick-start on the stand technique’, poising the right foot on the left pedal, pull in the clutch-lock, then finger the choke trigger beneath the twistgrip—which instantly crumbles to pieces of broken plastic.

That’s a winner then! Some of these road tests don’t always go to plan.

Following some plastic welding surgery, we resume where we left off earlier and, after a couple of spins, the motor fires right up. Being a warm summer day, the Laura engine barely requires much choke and the motor seems to settle down to a steady beat.

All seems OK, lights all work, horn, brakes, and despite having a working VDO speedometer set, which is probably over-optimistically graduated up to 60mph, we have our pacer to check the actual speeds.

The M-48 engine delivers a smooth and torquey pull-away as the throttle is turned open and, though the centrifugal pressure plate clutch engages the drive at fairly low revs, the motor accomplishes the operation confidently and without any need to pedal assist the take-off, thanks to the efficiency of its reed valve induction.

That sort of start always gives a good first impression.

We amble along a back lane at an indicated 20mph just to warm the motor, and get the feel of whether we think the engine is OK after its 30-year slumber. All seems smooth enough as we turn out onto the first long straight, so we give a little more throttle to indicated 25. The motor is starting to buzz a bit more now, and still feels quite happy, so toward the end of the straight we give a short full throttle burst up to indicated 28mph sitting upright, before easing down to tickover at the junction to the second straight.

Again we pull smoothly away without any pedal assistance required and manage to run up to an indicated 29 in a crouch along the flat, but just short of halfway mark on the dial.

Turning into the return section heading back to base, we determine to try for the 30 mark, and just about hit the target on the downhill run in a crouch. While the engine was still running smoothly and happily enough, it was clearly running out of puff at that speed due to the limited transfer and low exhaust porting in the cylinder.

A light uphill gradient followed our downhill run, and the motor tone distinctly changed to clearer two-stroke firing as it came under load on the climb to pull strongly up the slope.

Definitely a good performance for a standard engine straight after a 30-year sleep!

The cycle chassis handled confidently and well enough for any basic commuter moped. the 80mm front and 70mm rear brakes were adequate, though unspectacular, but satisfactory for the job, and all round, the Starglo delivered a very capable ride on its 2.25 × 16 tyres on Silverline Westrick pattern chrome plated rims.

The exhaust and carburetter induction was satisfactorily silenced at both ends, so you wouldn’t really notice either.

Coasting back into the garage, we only then discovered that the cut-out button had dropped off the IKJ switch, so it was no longer possible to kill the ignition (they were always cheap and nasty rubbish switchgear that fell apart on the NVT Easy Riders too). So pull on the clutch-lock starting lever to stall to a stop.

Comparing notes with our pacer reported 30mph for our indicated 28 upright run along the straight, and the same 30mph for our 29 crouch run along the flat, but a surprising clock of 34mph on the downhill run!

All a little faster than we thought … which is why we never believe moped speedometers.

The report from our pacer, however, was apparently fogged by billowing clouds of two-stroke smoke every time we were running on throttle, which couldn’t have been coming from the lean 33:1 semi-synthetic pre-mix we put in the fuel, so it was presumably burning off a 30+ year old mineral oil accumulation in the exhaust.

Batavus continued the MK4S Sachs powered Sports model right into the late 1970s and also built its last mopeds using Anker–Laura engines in the late 1970s, after which it reverted to Sachs and Peugeot motors.

The entire Laura Motoren factory was sold to South Korea and, after 1980, Anker–Laura M-56 engines were re-made in Korea by Daelim Motor Corp.

In 1981, Berini was also sold on to South Korean ownership, who used the brand for Berini mopeds in the Korean home market for a further 15 years.

A Pronto De Luxe with dual-seat was seemingly the last new Batavus added to the range in January 1983, and discontinued with the Mondial September, which represented among the last Batavus built moped models.

It had made and sold lot of moped models over 30 years of production, but returned to concentrate on its core business of bicycles as the moped market dwindled away with the emerging popularity of the 50cc CVT scooter … different times.

The Berini name returned to Europe again in 1998 under the ownership of the Alblas company of Rotterdam, who sticker-branded batches of imported Indian-built mopeds, remarkably fitted with Anker M-48 engines! Alblas still continues to import and market a new generation of Chinese-built Berini branded scooters, light motor cycles, and electric bikes.