Sponsored by Peter Vaughan

East Anglian Cyclemotor Club, Devon Section

and Lohmann Enthusiast.

Just lie down on the couch, close your eyes, and relax… Let’s prepare for a nice, leisurely voyage through time across three centuries…

Considering the machines involved, it’s going to be a particularly slow cruise, so we’ll just gently ease back through the past… back to old Victorian London in 1892, where German immigrant Carl Lohmann establishes his Lohmann Company as a bicycle manufacturer and trading office.

Fast growing popularity and demand for cycles meant business was good and, in 1896, he decided to form a sister company back in Germany, at Bielefeld, since this town was developing to become a major centre for the European bicycle manufacturing industry. One of Lohmann’s primary activities here concerned leather saddle work, and the German business began to establish its name, particularly in this sector.

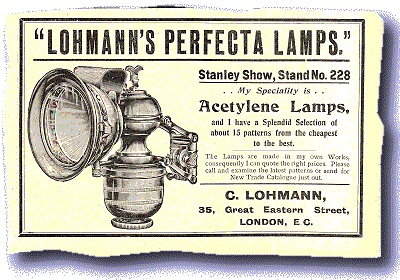

The two companies continued in parallel into the 20th century, where a 1906 advert presents ‘C. Lohmann’ trading cycle accessories, particularly carbide lamps ‘made in my own works…’ at 35 Great Eastern Street, London EC.

Advertisements in The Trader say that callers are welcome, so this address appears to have represented an actual business premises (rather than just an accommodation address for the registered office). Lohmann occupied stand 228 at the 1906 Stanley Show: "Here will be found a very full assortment of all kinds of cycle and motor cycle accessories, tyres, tools, frames, fittings—in fact, practically everything connected with the trade, besides also a complete selection of very suitable and saleable lines for the winter trade, such as phonographs, records, footballs, air-guns, mechanical toys, etc, etc."

‘The greatest speciality will be the Perfecta acetylene lamps, which include the Perfecta Nova, Perfecta Original, Perfecta Stella, Perfecta Simplex, and Perfecta Regina. All these well-known lamps have been considerably improved in construction and finish. Other lines include Superba saddles and tool-bags, which goods are also manufactured in their own works.’

Lohmann’s familiar ‘rays of light’ logo most probably came about from its Perfecta acetylene lamp products.

The advent of the Great War in 1914 presented particular difficulties for the British business division, since Herr Lohmann never relinquished his German citizenship, so the London Lohmann company had consequently been founded as a ‘foreign owned’ enterprise. Carl Lohmann died in 1916, leaving his family in Bielefeld to convert the German company into a private business, while the London assets were confiscated as ‘enemy property’, its equipment dismantled and dispersed, and the original British-based company disappeared. Following the armistice, the German Lohmann company continued into peacetime manufacture of bicycles and cycle accessories, production of saddles, tool bags, saddlebags and travel suitcases from its leatherworks.

With Europe sinking back towards conflict during the late 1930s, Lohmann was classified in the listing of National Defence Industries in order to produce military equipment, uniform leather accessories and motor cycle saddlebags, the demand for which kept the factory working at full capacity until the plant was at least heavily damaged, if not completely destroyed during USAF B-17 Flying Fortress air attacks on Bielefeld on 20 September and 7 October 1944.

During the closing phase of World War Two, when the Third Reich was suffering chronic fuel shortages, it’s widely conjectured that the Wehrmacht initiated research and directed some of its engineering scientists towards the design and development of various fuel-efficient compression-ignition engines capable of running on the crudest of basic fuels, such as paraffin.

1950 version of the Lohmann

9 May 1945: The Führer has committed suicide, Germany is overrun by Allied armies and Grand Admiral Karl Dönitz has acknowledged the nation’s defeat. The European war is technically over and, for arms manufacturers on either side, the end of a war signals lean days ahead, most particularly for any military-dependent manufacturer on the losing side, so it’s probably time for the business to look for something else to do…

The Lohmann company re-emerges in 1948 references, when former Wehrmacht boffin Hermann Teegan, now working for Lohmann Werke AG, is granted a French patent on 3 September, followed by registration of a further German patent on 2 October. These relate to a concept variable-compression-ignition motor, and on 3 March 1949, a further German patent was recorded for a different type of engine developed in conjunction with a team of other engineers. On 30 April 1949, Teegan applied for a United States patent on the same engine; the published drawings clearly describe and show the distinctive and unmistakable features of a new and unique cyclemotor engine that is about to enter development.

A prototype model engine was soon constructed, mounted onto a bicycle frame, and testing began.

Reports in the German press generated considerable public interest, which convinced Lohmann to seize the moment and prematurely rush the clip-on kit into production somewhat before it was properly developed.

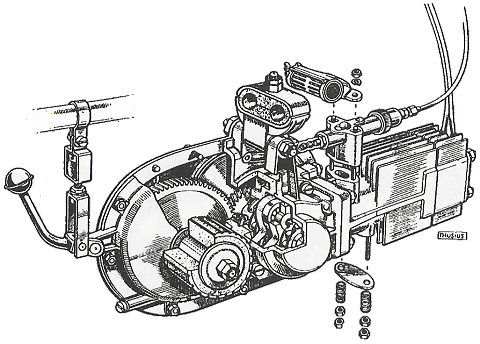

Even five years on in post-war Germany, low grade petrol was still in short supply, so there was going to be some obvious appeal for a small and economical engine primarily intended to run on paraffin. The tiny 18cc, 28mm bore × 30mm two-stroke engine was specified to develop 0.75bhp @ 6,000rpm (a comparatively high revs figure compared to conventional motors of the time) for a given top speed of 16mph, the power rating probably being based upon use with paraffin fuel.

The term Diesel engine applies to compression-ignition engines where the fuel is injected into the cylinder. While most Diesels are poppet-valved four-strokes, there are a few piston-ported two-stroke Diesels: the Deltic and the Commer TS3 being the most well known.

There is some debate about whether Rudolph Diesel should be credited with the invention of the Diesel engine; the main other candidate for this honour being Herbert Ackroyd-Stuart who patented a fuel-injection compression ignition engine in 1890, two years before Diesel’s patent.

However, Diesel’s objective was to obtain high fuel efficiency by building an engine that ran on a ‘constant-pressure’ cycle and it was this idea that was subsequently developed into the modern Diesel engine.

Because the Lohmann engine uses a homogenous charge rather than direct injection, it is not a Diesel and runs closer to the Otto cycle than to the Diesel cycle.

This engine is often referred to as an 18cc Diesel, mainly because it has no sparking plug or ignition system, and a Diesel engine might seem the nearest familiar engine to it. Diesels are generally characterised by injectors & poppet valves and operate on a four-stroke cycle. The Lohmann however complies with none of these, since it operates on a two-stroke cycle and conducts its vaporised fuel through transfer porting channels.

The Lohmann would now be classified as an HCCI engine, meaning Homogenous Charge Compression Ignition, which is a form of internal combustion where a mixed fuel and oxidiser (air) are compressed to the point of self-ignition. HCCI engines can be highly efficient since they generally function under relatively high compression ratios (even above 15:1) and on lean-burn fuel mixtures, which naturally results in low emission production. They will operate over wide load and speed ranges and, under optimum conditions can sometimes achieve higher efficiencies than conventional spark-ignition motors.

Downsides are that the operating conditions can be destructive to their mechanical components, they can be quite noisy and require efficient silencing, and the auto-ignition event is more difficult to control than in conventional spark-ignited engines. These have proved to be major hurdles to more widespread commercialisation.

Subsequent research has shown that the use of proportionally mixed fuels with different reactivities (such as petrol/diesel/paraffin combinations) can improve control of the auto-ignition event and burn rate, so further increasing power output, performance and efficiency.

Running mixed fuel combinations is called RCCI or Reactivity Controlled Compression Ignition (more on this later in the road test, and goes to explain some reason behind the East Anglian Cyclemotor Club’s acquisition of a fuel mixing licence).

As illustrated by press photographs from the 1950 Frankfurt Show machine, early examples of the Lohmann Type 50 cyclemotor varied from the later production engines by different cylinder, head, exhaust, and intake arrangements, which indicates the extent to which the design was being further developed in manufacture.

The engine was initially launched for sale in Germany and neighbouring continental Europe, progressing to further European markets as production established.

The British motor cycling press assessed and reported on the Lohmann as early as 1950, though the cyclemotor didn’t actually arrive in the UK until two years later when Britax concluded an importation and marketing agreement with the Bielefeld company, and advertised the engine for sale at 24 guineas at the Earls Court Motor Cycle Show in November 1952.

In Britain, the Lohmann was advertised to run on a conventional 2-stroke petroil mix at 25:1 ratio, though this was probably to avoid duty difficulties with the Inland Revenue regarding the use of low taxation fuels on the public highway. Running the engine on a straight petroil mix wouldn’t normally have been the recommended fuel type to suit the motor!

The Lohmann engine was said to be able to run up to 9,000rpm, though probably not under loaded conditions except maybe downhill, which would calculate to some 24mph, so we’ll see about that!

For our road test, we’re running an optimum RCCI fuel of 25% petrol, 25% diesel, 50% paraffin, and 25:1 2-stroke mix of semi-synthetic oil, which combination is blended for optimum performance.

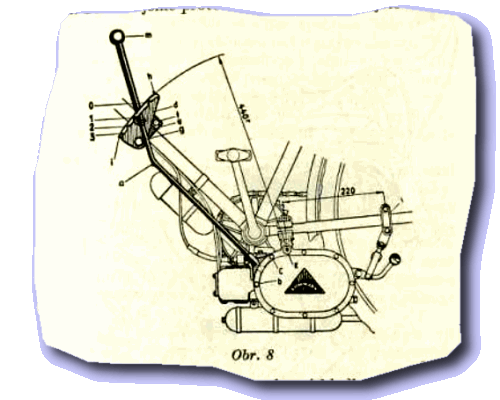

Our test machine comprises a period Germanic style swan-neck bicycle fitted with drop handlebars, and a specially constructed ‘pressure-set’, which under favourable conditions, allows the roller drive engagement to be adjusted to lighter contact to reduce frictional losses, and so improve performance.

To all practicality, this Lohmann is configured to deliver the maximum performance we can expect to wring out of one of these machines—so let’s go snail racing! Turn on the fuel tap … and that’s pretty much where any similarity to anything you’ve ever know before completely ends!

Since we’re running in dry conditions we notch the roller engagement into ‘light’ pressure using the big lever to left of the down tube. A firmer pressure setting is available for wet conditions where the rubber drive roller might slip.

There’s not really any carburettor as such, so there isn’t exactly a conventional choke in any sense that you might normally expect! The engine is supplied with its fuel by a gravity-fed fuel metering device, though this is controlled in conventional manner by a twistgrip throttle operated air slide, so that might seem easy enough to relate to—however, to really confuse things, the fuel metering unit has a ‘starting enrichment device’ that is also operated by the throttle twistgrip. The slide continues to open beyond the ‘full throttle’ position, which then starts to close the airway, but continues to open the needle jet, so enriching the mixture for starting. An extra spring on the air slide is supposed to make it possible to ‘feel’ when the choking function is being engaged, but in reality, you’re not really aware of anything happening.

On the left grip is what looks like another throttle twistgrip, except this set has a push-me/pull-you twin cable connection to operate compression release and variable compression control within the given range of 8:1 to 12.5:1 ratios.

Turn this left grip forward to decompress to more easily navigate our bike to the kerb, trigger-switch the cycle hub gear down to second, otherwise starting is going to involve excessive effort, then pedal away with the decompresser engaged to get the engine spinning and build up some momentum.

Turn the left grip up to maximum compression, keep pedalling, open the throttle, and keep pedalling … keep pedalling … there’s a plume of fuel vapour drifting out the tailpipe, but no combustion yet … keep pedalling … Argh! Just take a minute for a little breather.

There’s been a while since this Lohmann last ran, and it seems a little reluctant.

Our back-up rider has a go, with the same lack of result, so now there are two of us taking a minute for a little breather.

Our third attempt is finally rewarded by a clattering noise from below, which doesn’t really sound like an engine firing up in any normal sense. It’s more like something where all the bits are just loose inside and jangling about, rather like a motor that’s broken?

We continue pedal assisting the rattling Lohmann to run while twiddling the left and right hand grips to try and get some feel for what’s going on. By reducing the compression on the left hand grip the clattering noise abates, so that’s all compression related, but the engine firing also fades out, so we guess this might be because it’s still cold. After a few minutes of pedal assisted running up and down the road, we now seem able to get the engine to pull under its own power, so take a short run down the lane to work up some temperature before our test ride.

Now the bike’s been run again, further restarts prove fairly easy, or maybe we’re just getting the hang of this?

Tracked by the pace bike we rattle down the lane and towards the village outskirts, but glancing back we notice our pace rider is hanging well offside of the white plume of smoke drifting from below our mount. The now combusting cocktail of fuels produces smoke from what it burns, and dirty smuts from what it doesn’t burn.

We don’t think it’d stand any chance of compliance with modern emission standards.

The trick for controlling Lohmann is to keep the throttle pretty much open all the time (but not too open, or you’ll overfuel by engaging the choke), then balance optimum running by varying the compression ratio to suit the conditions. The engine generally knocks under excessive compression setting, and performance falls off as the combustion becomes premature. Turning down to drop the ratio produces a retarded rattle and reduction in power, then turn down too much and combustion will cease.

Somewhere in between these extremes is a happy medium, where the engine runs relatively comfortably on its best compromise setting according to variable conditions, being: engine temperature, incline or wind resistance. Just small changes in any one of these conditions may demand some fine tuning to the balance of compression and throttle setting to maintain optimum running, so the rider is constantly twiddling these controls in search of the ever elusive optimum setting.

You soon get to appreciate that the bike will not simply go fastest on full throttle and highest compression. Often the best performance may be found by backing down the compression twistgrip and regulating the throttle, so the whole Lohmann experience certainly requires adjustment to a whole new scale of values.

You can readily accept the need to pedal assist against even the shallowest of incline or headwind, since no one is realistically going to expect any 18cc engine to deliver much capability against even the mildest adversity.

The most satisfying feeling comes when you get onto a flat or light downhill run, then manage to tweak the compression set and throttle valve into optimum setting, and just briefly, the miniature engine crawls gently up to maximum speed, before the conditions change slightly again (usually a small gradient) and you’re back to twiddling the balance again.

It’s quite difficult to concentrate on finding an optimum control balance when pedal assisting the bike, so the engine often wasn’t overly helpful on hills, but a more practiced Lohmann rider and accomplished cyclist would probably manage to get a bit more out of the engine under such conditions.

In still air, fully crouched, and on engine power alone, our very best on flat paced at 17, and downhill run 20mph.

Even the downhill run isn’t simply a case of tucking down and giving it the beans, this still requires a perfect compression and throttle valve balance or the engine will hold back its top speed.

When we did get the tune right, the engine certainly seemed to handle its revs capably enough, and the maths says 20mph = 7,500rpm.

Since Lohmann motors have no generator set, the rider is compelled to resort to cycle lamps.

The lowly performance meant the cycle brakes were never challenged any more than they would be by the conventional cycle, and this machine had a three-speed coaster back-pedal hub brake, particularly suited to the Lohmann since the benefit of no distraction from operating a hand brake lever allowed the rider to concentrate on regulating best compression control at all times.

A Lohmann rider is certainly not going anywhere fast, but they’re going to be kept pretty much occupied by constantly twiddling the controls to maintain running performance.

The varying engine sound is something you sort of get used to and accept. With the large volume silencer and air filter/baffle there’s not so much any particularly distinctive exhaust or induction noise, as varying degrees of knocking, rattling and clattering that just sound as if the motor is falling to pieces inside. If it was really about to break, then you probably wouldn’t be able to tell any difference!

Upon parking, the exhaust soon starts to drip filthy smuts out of its tailpipe. A used Lohmann will readily develop an oily film about its parts, and after we took the bike back to the owner, the van smelt strongly of ‘commercial fuel’ for a good week afterward. Despite the undoubtedly frugal fuel consumption, there’s nothing clean or green about the claimed 300mpg economy of this microscopic cyclemotor, it’s a dirty little engine!

The Britax accessory firm initially began marketing motor cycles with importation of the Ducati Cucciolo cyclemotor engine in 1949, selling various versions of this Italian model until 1956. Britax didn’t stick with the Lohmann for long since sales proved very limited, and the 18cc cyclemotor only featured in their listing for 1953.

Lohmann sales pretty much plotted a downward curve shortly after it was initially established. There wasn’t anything particularly wrong with the engine, but just a change to the budget market environment that contributed to its decline. Cyclemotors in general were suffering falling sales as greater social affluence moved public focus more up-market towards mopeds, scooters, larger motor cycles, and cars. The brief moment of super-economy cyclemotors had become eclipsed almost as soon as it started.

Based from 1951 figures into established markets, Lohmann sales were down by 25% in 1952, 75% in 1953, 90% by 1954, and 97% in 1955.

People just weren’t buying cyclemotors any more.

Efforts to make up the collapsing sales numbers were made by attempting to extend distribution toward further markets. A Hispania marketed version was offered into Spain, Lohmann Motori srl was established at Milano to sell engines into Italy, before evolving into Ambimes srl at the same address and then, finally, Stucchi Cycle Co. became Italian concessionaires and established an agent in Switzerland.

The plummeting sales figures however reflected the generally despairing situation.

In January 1954, the American Popular Science magazine published an article on a mounting conversion of the Lohmann engine from cyclemotor to outboard propulsion on a canoe. The engine was pre-heated for rope starting by burning fuel pellets in a shield around the cylinder.

By 1955 it was pretty clear that the Lohmann had no future prospects as an auxiliary bicycle motor in the European market, and interest from the USA connection resulted in sale of the engine tooling to an American Company, which hired Hermann Teegan and established a research and development studio for him in Brackwede.

The German Lohmann company which manufactured the cyclemotor engine went out of business in 1960, while Teegan continued to work on the development of a 125cc HCCI motor cycle engine until his sudden death in 1962.

Work had initially started on design of another compression/ignition engine of 125cc capacity early in 1950, and by 1951 a working prototype was undergoing extensive testing. The engine was intended for installation in an unusual Lohmann-built scooter-cum-sidecar three-wheeler combination in one unit, which streamline faired hybrid was initially shown as a prototype, and reportedly powered by a proprietary 200cc Sachs or Ilo 2-stroke motor.

Teegan’s untimely demise at 62 brought an abrupt halt to his projects, and all tooling was abandoned by the American Company, who wrote off the episode and moved into other activities.

Contrary to any impression the reader may have concluded of a fading cyclemotor being marketed by a failing company, Lohmann sold over 51,000 of the engines across a five-year period, which was no mean quantity, and surely shows that, however briefly, the tiniest cycle attachment engine certainly had its moment.

So having concluded our Lohmann chapter in 1962, we now seem to arrive at a natural break.

It’s not uncommon for our main features to cluster different machines in a comparative article—but what could anyone fairly match with a Lohmann? There was nothing quite like it ever made at the time, or since.

Nothing else so small, or so feeble!

So what might be run with an 18cc ‘Diesel’ engine to make a packaged feature?

No, we honestly couldn’t come up with any other cyclemotor, but how about something else that might similarly represent another slowest powered vehicle on public roads in its own respective time?

It occurred to us that the 60-year-old Lohmann cyclemotor might be comparable to an electric bicycle?

Intrigued? Read on…

While presenting other articles, we’ve incidentally encountered some odd electric powered contraptions along the way: the Winn City Bike, the Solo Electra, the Garelli Katia Electric—all small-wheeled scooter-peds, massively heavy, and generally economic disasters. There were certainly various other battery propulsion attempts, but early electrified efforts were generally held back by limited range and top heavy power to weight ratios—so let’s have a look at one of these…

Marketed by TGA Electric Leisure of Sudbury, Suffolk, the first TGA Electrobike Kit was a fairly early pioneering effort to commercially produce and market an attachable electro-booster set to a bicycle by fitting a 200 Watt, 12 Volt motor with integral reduction gearbox made by Electric Motor Developments (EMD) of Halstead in Essex.

Our particular Mark 1 Electrobike booster set seems to have experienced several installations over the years, coming to its present owner on a gents cycle frame as a rear mounted fixture, and driving the back wheel through a three-speed epicyclic hub. This set-up however, failed to accommodate any pedalling capability, so left the machine stranded if the battery went flat.

Its heavy 12 Volt lead acid car battery mounting on a frame above the rear wheel, was an awkward location, giving a high centre of gravity, and registered handling difficulties for the comparatively lightweight cycle frame.

With the gent’s crossbar presenting mounting problems to its elderly rider, the motor unit was relocated to a lady’s step-through frame, front-wheel driving a three-speed hub rear wheel fitted into a splayed fork. This retains the option of three driving speeds for the motor, while a second three-speed wheel in the back returns the same possibility to cycling assistance.

With the heavy 12 Volt lead acid car battery and its control functions relocated to the forward basket; it’s now the front-end that gives the weighty handling difficulties.

The key activated solenoid is now triggered from the right handlebar by a simple push button, which has replaced a graduated throttle control. The old ‘speed control’ was found to be ineffective since the machine needed to operate at full power pretty much all the time in order to maintain pace.

In deference to risk of overloading the motor, straining the drive chain and shocking delicate sintered gears in the epicyclic gearbox, it’s better to pedal the cycle up to speed then engage electric drive, just to maintain the pace. Operated in this means, the e-motor took over gently and smoothly.

Running the driving wheel in first gear generates around 8mph on the flat, up to 12mph in second gear, and up to 15mph maximum in third.

The installation was somewhat rudimentary at the time of our test, and we had to ‘work around’ a number of ‘unfinished’ aspects.

Though a healthy 12 Volt supply battery can reportedly offer a 20-mile range on a full charge, it needs to be appreciated that rider assistance will be required to build up speed and on inclines.

This early amalgam of 12 Volt propulsion motor, with a bulky and high-mounted lead acid car battery mounted on a bicycle is, to be honest, a pretty inadequate and dreadful combination. It barely matters whether such a heavy battery is located to the front or rear, since it renders the bicycle very difficult to manage, and is courting disaster when the machine falls over (and it’s surely going to do that occasionally).

It’s difficult to effectively date this TGA drive unit (with a notable mention that enquiries to the company found them totally disinterested and disappointingly unhelpful), but we’d probably place it around the late 1980s to early 1990s?

A 12 Volt system really isn’t man enough for this task, and a car battery is too cumbersome for the application.

We think the kit may originally have been supplied with a sealed lead/acid-gel battery, but in the 1980s, any smaller and lighter battery only meant less power and less effective range.

TGA Electrobike Mark 2

For an electric bicycle to work as a viable proposition, is going to require something more practical than this sort of DIY improvisation.

What the e-bike needs is more power, less weight, a lower centre of gravity, and basing around a purpose-built machine rather than a common bicycle, which would probably never seem up to the job.

The Mark 1 kit was subsequently replaced by a 24 Volt Electrobike Mark 2 version retailed as a complete bicycle, where the motor mounted beneath the main down tube of a ‘shopper’ cycle, and driving a secondary freewheel sprocket at the pedal crank. The motor was controlled by a graduated throttle and could be assisted at any time by normal pedalling. The rear wheel employed a conventional three-speed hub, so the bike might develop a fair performance provided good battery condition and charge remained, though the rear carrier now had to contend with 2 × 12 Volt sealed lead/acid-gel batteries connected in series, so the weight issue remained.

The Electrobike is believed to have become discontinued around the later 1990s.

According to urban legend, the 24 Volt drive motor was an adaptation from a commercial vehicle windscreen wiper motor, but the further myth and mysteries regarding these machines remain unanswered since enquiries to the company only found them totally disinterested and disappointingly unhelpful.

TGA still exists as an electric mobility products company, but has long ceased involvement with cycle related products and supports no spares or information for them.

Progressing into the 21st century, electric bike technology has really been moving forward over the last decade, with advances in both motor efficiency and battery cell development…

There doesn’t seem a lot of background available on our Koolgachet e-Cycle. As far as we can tell, the bike appears to be built in Spain, with the trademark registered to Asian Pioneer Espana SL. The cycle chassis is made from cast aluminium, while the motor hub and a number of the cycle fittings appear likely to derive from eastern origins, and the removable battery is quoted as 36 Volt @ 12 AH, with a 4 hour charging time.

When Koolgachet is ridden as an ordinary bicycle with the ‘ignition’ keylock in the ‘off’ position, the single ratio proves quite low, so it can only be pedalled up to a frantic maximum of 12mph, and around a mere 8 to 9mph seems the most sensible practical pace.

Switch to ‘ignition on’, and battery assistance comes in with a motion sensor as the pedals turn forwards (backward freewheel rotation does not enable drive). Initially it feels rather like receiving a push from behind, and the speed can be built up as long as the pedals are kept turning, to a best of 14mph along the flat, and paced maximum 19mph running downhill. Turning the pedals is only a no-load rotation to keep the power on, and quickly becomes a very pointless irritation to the rider.

Presumably however, there is an electrical load sensor on the motor, since the moment the cycle encounters the slightest incline, the E-motor stops contributing when the rider would seem to want it most! While this is all very good for extending the bike’s range, it leaves the rider doing all the hard pedalling whenever there’s any real work to do. It’s like having a motor that only does the easy jobs!

E-Cycle is fitted with calliper cycle block brakes at front and rear, which prove adequate enough for the limited performance. The brakes are operated by conventional cable, but also have wires coming out from switches in the lever brackets, that cut off the power to the motor when the brake levers are pulled.

Being a folding machine, there’s probably some expectation that the bike may need to be stowed into a car boot. No problem there, after a battle with the fasteners, it will fold up to fit into a confined space OK; the surprise comes when you try to lift it in. The first attempt results in the bike staying firmly on the ground with the shock discovery that this little bike is, in fact, pretty heavy—37kg, nearly 6 stone in real money, so little wonder that picking it up becomes a double-take! Most of this weight is, of course, the lead/acid battery, which can make the loading job easier if you separate the battery first.

Apart from Koolgachet’s small wheels giving the usual impression of a rather unstable ride, the stem clamp didn’t seem to lock up the folder handlebar set securely, so the whole steering head rocked disconcertingly side-to-side. We tightened this up as much as possible, which did address most of the slackness, but still didn’t wholly resolve the problem, and we weren’t at all convinced the assembly wouldn’t come loose again. Despite tightening the saddle-stem locking clamp as much as we were able with a big pair of pliers, the stem still kept creeping down the tube as the bike was ridden, with the conclusion that these folder fasteners are probably not man enough for the job.

We also noticed several spokes missing from the rear wheel, presumably having been removed after breaking, and the rim ran out of true as a consequence. Overall, there is an impression that build quality may be a little lacking.

We had several people try the e-Cycle, and couldn’t find anyone who liked it at all.

Conclusion: Koolgachet isn’t cool at all, in fact, we think it’s pretty naff!

If electric bicycles are going to save the planet, they’ve surely got to get a whole lot better than this!

Decals on the rear body panel read "CTEB - Classic Electric Bicycle", but these stickers are fairly meaningless since the machine is made somewhere anonymous in the Far East, and could be bought in to any country in the world and badged up with anything the importer likes. In this case the machine is marketed by Pyramid Products Ltd of Nottingham.

Though technically classified as an Electric Bicycle, this machine is basically an E-scooter.

It doesn’t really matter what this machine might be called, or where it may originate from, because if the bike has any soul at all, it’s probably made of plastic!

The cast alloy wheels are shod with 16×2.125 tyres, and powered from the rear by three series-connected 12 Volt × 12Ah batteries, for 36 Volts.

There are a few given specifications for reference, net weight (excluding batteries) 38kg, maximum speed given as 15mph, range 35 to 50km, motor power 180 Watts and, for the scientifically minded, motor torque 8.5Nm

The drive motor is built into the rear hub, and the rest of the scooter is fully appointed with pretty much all the electrical gizmos and goodies you’d expect to find on a normal petrol-engined scooter, headlight, taillight, flashing indicators, a bleeping horn, battery charge condition meter, and power (ignition) indicator.

A speedometer in the handlebar console indicates in blue 3mph steps up to 15mph, and then continues in red 3mph steps up to 24mph.

There’s a pair of handlebar mirrors fitted as standard, and a couple of intriguing stickers applied to the console moulding, "In order to reduce motor strain on starting, and on inclines, always push or pedal when starting off".

And one by the throttle: ‘In order to be street legal, do not disable the pedal mechanism with this red button when using the bike on the highway’ … and, under the throttle, is a red button marked ‘S–P’.

The battery container is found by lifting the foot mat, and has a connection point to suit the charger, but you don’t need to take this out for charging since there’s another connection point on the frame under the front of the seat, which doesn’t require disturbance of any fixtures when plugging into the socket.

The machine may look like a scooter, but its cycle basis is quite apparent in the calliper front brake that is tucked away under the front nose. Rear stopping is by a cable operated band brake unit attached to the hub. Generally, the rest of the cycle is fairly well appointed with storage capacity too, including a small locker in the front leg shield assembly, and a fitted rear rack topped with a lockable plastic box carrier.

The seat also lifts up in typical modern scooter fashion, to reveal a crash helmet style storage bin beneath, except of course that you’re not obliged to wear a helmet on an e-bike, so might be considered more likely storage for the shopping.

There also seems to be yet another charging lead coming out of the rear of this compartment—how many charging points does a bike need? We make this three now!

There’s also a bag in the bottom with a few supplied tools, spare fuses, a couple of screws, and a plastic moulding, so we don’t know if these might be important parts that are meant to fit somewhere?

The bike very confidently mounts a dual seat and is fitted with folding back footrest plates from the rear axle, so is plainly pertaining to be suitable for carrying a passenger.

Where the ‘pedal assisted’ aspect really falls down is in having the cycling set fitted to a scooter body, since the pedals are splayed 18 inches apart, which any serious cyclist would tell you is utterly ridiculous for any proper use! Not only that, but the pedal arms are just a snap fit, retained by spring loaded bearings onto a half-inch square crank spindle, so they rather wobble about in any attempted operation.

On an initial test ride, we pedal assist away like a good little cyclist, and in the usual fashion, the electric motor kicks in as long as you keep turning the pedals. The electric motor seems arranged to deliver more power at the 3mph steps as indicated on the speedo, according to the rotation pace of the pedals. So the scooter goes quicker if you turn the pedals faster, but involves no physical effort since the motor is actually delivering all the power to push the bike along. All this no-load rotation is really pretty pointless just to keep the motor driving, so it doesn’t take long before we get very bored with that. So, should we push the naughty button? It’s coloured red for danger, but just asking to be pressed and find out what it does. But if press it on the public highway, we’d probably be in contravention of the EAPC regulations 1983 EU Directive 2002/24/EC, and we don’t want to risk having the full weight of European regulators bearing down upon us—so instead, we take the bike to our own personal test track, secretly located on a private estate in the quiet Suffolk countryside.

Ignition on … pedal off in the usual manner … the electric motor kicks in … 6mph … 9mph … push the button! Ah, I see, it’s disabled the requirement to keep pedalling, and you can now control the speed on the throttle in the manner of a normal scooter.

On the flat in pedal mode, the speedo can indicate up to 16mph, and on the throttle, much the same, but without the pointless nonsense of the stupid no-load pedalling.

Probably the best way to use this E-scooter is to pop off the pedals, since they’re just useless rubbish, and chuck them in the back box, scoot the bike away for initial take-off, then just ride it on the throttle like a normal scooter. So, with our legs now tucked in behind the leg shield for best streamlining, sitting right back on the seat in lowest crouch, with eyes just peeping above the tiny fly screen, what’s the best we might wring out of the poor little E-scooter on a long and shallow downhill run … 18mph!

Thanks goodness we weren’t trying that on the public highway, we could have frightened ourselves to death!

There’s a proper motor cycle style centre stand for secure parking, the lights were reasonable, better than the average bicycle, but the rear indicators were placed too close together in a central cluster, and we felt any following vehicle probably couldn’t make out which way the bike might be going.

The telescopic front and swing-arm rear suspension worked well enough for the low speeds involved.

The brakes worked adequately, though the rear stopper produced a lot of complaining creaks and groans in application.

Trying to use the E-scooter on the pedalling set was pretty awful, as the 18-inch splay was ungainly and difficult and, presuming the battery went flat in the middle of nowhere, the slack, removable arms on the cranks never felt as if they would be of any serious use for pedalling back home on.

On the plus side, this scooter appeared fairly capable of reasonable electric propulsion under its own motive power, so did feel as if the motor was making more effort than the Koolgachet.

Let’s face it, if someone buys any bike with a motor, be it petrol or electric, it’s because they don’t really want to be pedalling much, so the sooner the regulations get over this ‘pedal assisted requirement’ nonsense, the sooner the electric bicycle may grow up to become some useful transport in our choking urban centres.

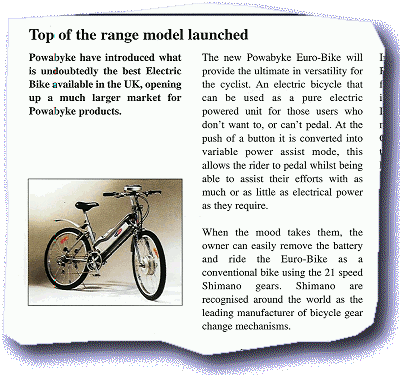

Our search for a better electric bike leads us onward to another machine that someone from the trade recommends … "You want to try a Powabyke, they’re pretty good".

This is obviously another Far Eastern manufactured E-bike, this time imported by Powabyke Ltd of Bath, UK.

There seem to be several models available, but we just have the basic "5 Speed Euro" model with rigid frame and rigid fork.

The chassis appears to be largely based on a modern conventional cycle design, and is not trying to be clever or gimmicky like the Koolgachet, or pretending it’s a scooter like the Pyramid. If someone is going out after an electric bicycle, then that’s exactly what this is.

From headstock to saddle tube, there are three main frame rails which form a cradle in which the sealed lead-acid gel battery pack nests. The triple tubes form an excellent sturdy frame for the cycle, and the rest of the bike appears much like a robust mountain bike. There’s a six-speed derailleur gear set on the rear wheel, and driven by a conventional cycle pedal set at the bottom bracket means that the rider is expected to be able to add some useful assistance to extend the vehicle’s range and effectiveness.

The whole Powabyke package looks much more promising already. It’s taken some 150 years to develop the bicycle to the pinnacle of ergonomic efficiency that the modern cycle has become today, and its evolved functionality isn’t going to be improved by pretending it’s a scooter or by trendy design.

Powabyke doesn’t have any speedometer, lighting set, or gimmicky indicators—it hasn’t lost sight of the fact that it’s basically a bicycle, so you simply fit cycle lamps.

Electric bikes are technically regulated to around 15mph performance—typical cycling pace, so you don’t need anything more. You don’t need a speedo to tell you whether you’re doing 10mph or 15mph because you won’t be breaking any speed limits and it really doesn’t matter, and you don’t really need flashers since you can easily indicate with hand signals (like few cyclists seem to do anymore).

When the money you’re not paying for this unnecessary marketing junk is then redirected towards producing a more effective e-bike, then the rider is likely to get a better machine.

The only ‘instrumentation’ on Powabyke is a ‘battery charge LED indicator’, which shows its level of power reserve in a graduated bar display. A practical and simple device that suggests the remaining range, and can be easily seen in the dark. The battery can be recharged on or off the bike.

Both saddle and handlebar heights are adjustable in the conventional way, so most riders should be able to adjust these to a preferred setting.

Located forward right of the battery box, the three-position ignition key switch has off; drive mode—where power is controlled by the twistgrip throttle above 2mph, below this speed the motor cuts off; pedal mode—which gives throttle controlled assisting power while pedalling remains constant.

In ‘drive mode’ the range is given as 32km/20 miles, and ‘pedal mode’ 50km/32 miles.

The electric motor is located in the front hub and brakes are just conventional rim acting cycle callipers to front and rear. The six speed derailleur is simply switched by a single trigger on the handlebar, and offers a selection of relatively low ratios that are unlikely to much exceed the design speed of the general e-cycle, but are obviously specifically selected to best assist its working operation. It should also be appreciated that any E-bike is invariably a heavy machine, and if you may find yourself having to pedal when the battery has run down, then high ratios would likely to become quite hard work.

Weight of bike with battery is given as 38kg (84 pounds or 6 stone if you prefer), so a fairly substantial consideration to pedal or if you’re lifting the machine. You can of course use the E-bike as a normal bicycle by simply removing the battery, which reduces the weight by a third, down to 26kg (57 pounds or 4 stone).

In ‘drive mode’, just a fractional rotation of the pedals kicks the motor in and Powabyke pulls strongly to accelerate as the twistgrip is opened. The throttle delivers power that really convinces us that the motor is putting in some effort. Any rider wouldn’t begrudge helping the motor along when it’s working hard, labouring against a hill or headwind, because this bike really feels as if it’s doing its share.

The Powabyke can be readily switched between ‘drive’ and ‘pedal’ positions while in motion, and a rider can always pedal assist whatever mode it’s in.

Testing performance in drive mode for effective comparison, our best on flat paced at 16mph, and downhill with a tailwind made 20mph, though this was probably achieved as much by freewheeling up to speed since the motor should have stopped delivering energy beyond its design maximum.

We didn’t like the saddle, which vaguely wobbled around on its springs, like sitting on a jelly!

Also, while the low handlebar position may have helped reduce rider profile for lower drag, it tended to put weight on your hands, so particularly feeling the shock from road bumps, and readily induced tiring of the arms.

Maybe this will be the last of the E-bike tests in this particular feature, since this brand new BM Freedom is pretty much the latest thing in Lithium-Ion battery technology.

Li is currently being popularly heralded as the great new battery technology due to its lightness and fast charge abilities, but only time will tell whether it might just bring along a whole new load of problems regarding environmental disposal of its toxic compounds, or the occasional spontaneous combustion of some of Li’s suicidal electrical systems.

Passing all of the peripheral political issues by, since we’re really only here to look at the bike…

The ‘Freedom’ cycle chassis is a typical modern construction formed lightweight alloy, this version being a folding step-through configuration, though other frame styles are available in the range.

The drive motor is built into the rear hub, but is assisted by a 7-speed Shimano derailleur gear set. The handlebar trigger to operate the gear change is pretty neat, you pull a trigger to change down the range, but just push a button to progressively change up one gear at a time. The simple and easy selection method probably goes towards some incentive for the rider to actually use the system rather than leave it in just one generally acceptable gear.

The Li battery pack runs up behind the saddle stem tube, and has a key switch at the top for off/on, and a charging point socket. At the top of the battery pack there’s a row of indicators on a small panel, activated by pressing an adjacent button, which lights up to four green LEDs to indicate the level of charge within the battery.

The 36 Volt LiFePO4 battery is rated 10Ah, and described as a new type claiming a 10-year effective life and capable of appreciably more charging cycles than first-generation Li cells. The new Lithium Ion Ferrite cell is also being claimed to resolve the spontaneous ‘bursting into flames’ problems of the early Li systems, so we’re feeling a little more comforted by that news.

There’s another small control panel on the left handlebar, which comes up with LED illumination to indicate +/- switchable motor assistance levels of low/medium/high according to whether the rider may wish to contribute more or less cycling effort, which will affect the vehicle range.

There’s also what appears to be further battery health indicator constantly displaying on the control panel in up to four illuminated red LEDs, so the rider remains conscious of the bike’s capacity.

There’s another button on the panel, which turns on and off the LED headlight, which seems to operate from the Li battery set. The back light is separately switched on/off underneath the rear lamp, and has no visible wiring, so we presume this to operate from its own internal battery. The lights are supplied as standard equipment.

Under the right handle grip is a red button, which UK law would probably call the naughty button, since by clicking this, you can change from ‘pedal assisted mode’ to the ‘technically illegal in the UK’ throttle mode.

This is a peculiar arrangement, with the inner half of the twistgrip rotating to control the throttle, and the outer half remaining stationary like a fixed grip. Quite honestly it’s pretty stupid to operate, and we really can’t figure out any sensible reasoning behind it.

The calliper front brake creaks and complains in operation, but the rear calliper brake seems to work better, and without any protests.

The front fork has a shock absorption suspension system, which works very well to absorb front end jolts, and is a noticeable improvement over any rigid fork set.

The rear cycle frame is rigid, with a tidy little side stand fitted off the rear axle. The prop-leg works very effectively to stand the bike, so it’s not just for show.

Having assessed our steed, and investigated and fiddled with the buttons, it’s time to give it a go.

Click on the ignition, mount up, and pedal away in ‘low’ mode. The motor kicks in behind your pedalling, but if you stop rotating the pedals, the motor cuts out too.

We switch up to ‘medium’, then to ‘high’, which both still require pedal rotation to maintain the E-motor delivery; it’s just that the motor delivers its power harder and more readily in the higher positions.

Probably the most annoying aspect to usage in pedal mode is the way the E-motor delivery comes in a series of punches.

You receive a punch of power, which pushes the rider faster than the constant pedalling speed, so the motor cuts off again, then as loaded pedalling returns to the cyclist, the system delivers another electric punch. The effect is that you feel like you’re going down the road in a series of lurches.

The ‘throttle’ button turns on the twistgrip, so you can now smoothly control the speed motor cycle style, and without the relative nonsense of no-load pedalling, though you can still pedal to boost the machine if required to help on an incline, etc.

If the bike is stationary in throttle mode, any twist on the grip will find it eagerly snatching to accelerate whether you’re on or off the bike, so it’s a bit like an automatic scooter where you can’t really blip the throttle. The only difference with a motor scooter is that you are reminded of this by the sound of a running engine. The E-bike is completely noiseless, so it may seem a bit odd that it reacts so silently.

We were quite impressed the way Freedom would accelerate on the E-motor, and did feel as if it covered the same ground a bit quicker than our previous electric bikes, but the Freedom has no speedometer to present any suggestion of its performance. Perhaps it might have been delivering toward the upper end of the 14 to 16mph specification? The light downhill run felt fast too, and the E-motor delivered quite good power to make a useful effort against an incline. The 7-gear range allowed the rider to easily select an ideal ratio to work with the bike against different inclines, so it was natural to feel you could be pedalling with the machine if you wanted to assist, or be its master and make it do the work if you preferred.

On returning to base our tracking vehicle reported a paced top speed of 20mph along the flat and the same 20mph on the light downhill run. This slightly better than expected performance might be explained in that European electric bike specification for on-road use now seems to be rated as 250 Watt power rather than qualifying a speed limit, so more efficient motors may be able to achieve slightly better performance within the specification.

There’s also a more powerful 350 Watt version specifically designated for off-road use only, so nobody would be ever be using one of those on the public highway now, would they?

The other remarkable thing about the Li-bike is the weight, or rather the relative lack of weight. Unlike all the other ‘ten-ton’ lead-acid gel battery machines, you can very easily lift the Freedom for practical handling. This makes its folder function even more sensible, since you can readily lift the bike in and out of the back of a car without the need for a crane!

We stuck Freedom on the scales and it weighed just 3 stone 12 pounds, 54 pounds if you like payment in Pounds, or 24.5kg for the rest of the Continent who may only relate to Eurometrication.

So, might the modern E-bike be considered a latter day Lohmann?

From very different generations, the two machines perform fairly comparably.

The E-bike is probably cleaner and easier to use, but will any of them still be working over half a decade later, and will any E-bike ever achieve the curious charisma of the world’s tiniest clip-on engine?

Dating around 1953 makes our Lohmann cyclemotor nearly 60 years old at the time of test, and still working fine—but would any electric cycle still be working at that age? Would a replacement battery even be available when the original expired, and would the ailing cycle chassis even be worth buying one for at further extortionate cost? This all seems rather unlikely. Electrical technology is moving on so quickly that any generation of electric bikes seems likely to be headed for the bin within the same decade.

It’d be very hard to imagine any present day E-bike rider ever coming to terms with the dirty fuel mixing and challenging control processes involved in operating a Lohmann. The modern electric bicycle is certainly much cleaner, more practical, efficient and easy to use than the antique cyclemotor—but is any E-bike ever going to achieve the legendary and mystical fascination of Lohmann’s 18cc ‘Diesel’?

No, off course it isn’t, all modern E-bikes are going to be nothing more than disposable technology.

Lohmann cyclemotors in reasonable working order may now be fetching similar prices to a brand new electric bike, but the sixty year old Lohmann is probably the better investment.

Next: Far out, in the cold black gulf of space, great celestial bodies move relentlessly in their eternal orbits.

Planetary alignments are approaching perihelion point when we are going to be closer to this tiny globe than for many years, so maybe it’s time to prepare for another journey across the void.

The prophets say this sign is moving into retrograde, and stars foretell an end of the world—could this be the last mission as the planet plunges toward the sun in a glorious final dive?

Mercury boils at just 357°C, and this might be Meltdown.

[Text and photos © 2012 M Daniels. Period documents from IceniCAM Information Service.]

Life in the Slow Lane was a very long article, and correspondingly, the production notes are similarly large.

When we decided to produce an article on the smallest cyclemotor, the initial thought was that it could only really be as a stand-alone mini-feature, since it seemed highly improbable that there would be anything equally feeble enough to fairly compare with this antique auxiliary motor—until we received an option to sample what may be perceived as Lohmann’s modern equivalent!

So a flash of inspiration finds IceniCAM with probably the most unlikely feature that one might ridiculously imagine, as we match up the most fractionally powered machines from some 60 years apart.

Our titanic clash between a Lohmann 18cc ‘diesel’ cyclemotor from the 1950s versus the technology of 21st century electric bicycles was initially going to be called "Snail Racing", but ended up as "Life in the Slow Lane" as an anti-tribute to The Eagles song title, though a vestigial reference to snail racing remained in the text.

The "Slow Lane" feature has been around on IceniCAM’s distant horizon for several years now.

The Lohmann came from IceniCAM’s own stable, being one of Andrew’s personal collection, so we didn’t have to go far for that.

A date of April 2009 on the Lohmann photoshoot pictures presents an interesting contrast to the road test date of October 2011, and it’s not very often that features develop in quite that manner.

Our preceding Front Wheel Drive feature on the Cymota and GYS clip-ons presented two machines fairly comparable to each other, but trying to imagine any other cyclemotor competitively paired against Lohmann’s tiny compression-igniton engine would be difficult, since there really isn’t anything quite like it.

The Lohmann would seem to be the world’s smallest (and feeblest) production cyclemotor engine (unless of course you might know differently?), so what might we match with it? Even the first generation 25.7cc Cyclemaster motor wheel presents a mighty 43% capacity advantage, and obviously crushing superiority even before getting out of the starting blocks.

Possibly the original Berini M13 with the associated frictional losses from its roller drive arrangement might disadvantage the performance from its 26cc Pluvier engine a little, but it’s still going to be way ahead in the power stakes.

Just when we’ve pretty much accepted the seemingly inevitable conclusion that the Lohmann was going to have to run as a singular test feature, along comes our sixth Mopedland story as Year of the Cat in July 2010, with a passing association between an ancient Lohmann and a modern electric bicycle… yes, that’s it, that’s what we’ll do!

All we need is an electric bicycle for comparison, but so many to choose from? As usual, it’s not so much a matter of picking and choosing, more just a case of what we might be able to get!

As it happened, we got rather more than we expected!

Our first opportunity was the Spanish built Koolgachet E-bike from Zena Bamberger in early September 2010, which started first development of the text when the Koolgachet became the first of our machines actually tested—she didn’t like it, and neither did we! As a first impression of an electric bicycle it wasn’t very impressive, just heavy and sluggish, and required the pedals constantly no-load rotating to drive, even though they weren’t contributing to the propulsion—whose stupid idea was that?

Then came the Pyramid E-scooter from Clive Bamberger later in September 2010, freshly fitted with a brand new battery set for optimum performance, and switchable from its silly no-load pedal mode to a technically illegal ‘throttle’ mode.

The scoot went OK in electric drive, and proved best to ride with your feet on the footplate after removing the pedals since they stick out dangerously and tend to catch things (like your shins!). However, the width of the scooter deck, unsuitability of the scooter style seat and its position, and crummy QD square drive crank arms of the pedals gave a hopelessly ‘splayed’ pedalling posture and rendered any form of useful cycling assistance practically impossible.

With its sealed lead acid gel batteries positioned in the footdeck, the Pyramid achieved a low centre of gravity, but still remained seriously heavy and presented nowhere to lift other than easy-shatter cheapo plastic body panels.

We still remained unimpressed by the E-bike experience.

There must be something better than these, so what did the trade recommend?

"You want to try a Powabike, they’re pretty good"!

So next up was Terry Smith’s E-Powabike in June 2011, which seemed appreciably better as the E-motor proved pretty strong on the switchable throttle, while you could further pedal assist to also effectively use it as a bicycle.

Still however there remained handling issues with the high centre of gravity and weight of the battery.

Might the progress of modern technology offer the final E-bike solution in the form of the Lithium-Ion cell?

Zena Bamberger now seems to find all she wants from her BM Freedom in October 2011, an easy step-through frame, unparalleled lightness for practical handling, folding capability for convenient transportation, and the ability to pedal like a proper bicycle.

Only time may tell the durability and economic replacement of the LiFe batteries, and maybe if limiting legislation doesn’t hold back further development and performance (15mph/250 Watt limit), then the E-bike may possibly generate a wider transport appeal towards saving the beleaguered environment and relieving our congested roads.

We think electric bikes might be more practical and safer if they were able to keep up with urban traffic pace, 30mph?

The TGA Mark 1 Electrobike was our final E-bike, which turned up at the eleventh hour from Nick Bence-Jones.

Being an interesting and locally produced early electric bike example, we decided it had to go in too—but were much disappointed that the manufacturer was so completely disinterested and unhelpful regarding enquiries about their old products, which probably tells you everything you need to know about today’s TGA!

By now the article had now grown to vast volume! What to do with such a massive feature, and how would there ever be room in the magazine for anything else?

Danny simply handed the problem on by just mailing all the files to Andrew at the last minute, then jetting straight off to New Zealand on more road tests—so down to editorial decision how to cope with it all?

Can the modern E-bike be considered a later day Lohmann?

From very different generations and totally polarised technologies, the two machines do perform fairly similarly, so we thought it was a pretty fair and interesting comparison match.

The E-bike is probably cleaner and easier to use, but will any of them still be working in 60 years’ time, and will any E-bike ever achieve such mystical fascination as an 18cc ‘diesel’?

Costs for "Life in the Slow Lane" were pretty minimal, various local collections and returns probably amounted to only around some £10 of diesel fuel. In the interests of promoting compression-ignition cyclemotors, fellow Lohmann rider Peter Vaughan from Devon very generously sponsored the article.

It wasn’t so much a case of sponsoring the article, as sponsoring the extra production costs of presenting such a bumper edition! By featuring six bikes in the one article, "Life in the Slow Lane" had grown to a completely impossible size (as have these production notes!), and without Peter’s very significant sponsorship it would have been difficult to see how IceniCAM could have managed all the additional printing and postage costs for the hard copy magazine versions. There was a point at which we were seriously considering having to hold over the second and third features, but Peter’s donation made this possible—our biggest ever magazine.

Hi Mark,

I was reading your reviews on this bike as we own one, and a little information for you. The space under the seat is for a helmet, or you can buy a back-up battery pack. That’s what the other plug is is for. Also, the double key position is for switching over from one battery to the other.

I don’t know if your interested in this information but I enjoyed what you wrote—thanks again and keep it up.

J Culleton

Dear Sir,

Nosing through the Internet, I found a reference to a Japanese company, and thought it unlikely to be widely known there was a legitimate Lohmann copy out there.

Daniel Nicholls

In the Company History section of Aisan’s website, it says:

A Technology provision agreement was concluded with Rohmann [sic], Germany, and the production and sales of the Spit AS Type bicycle engine began. This was ‘the ultimate engine’ with a variable compression mechanism and pre-mix compression hypergolic system, but the production stopped after only 1 year due to a variety of problems including those with its start-up performance and durability in low temperatures. It became an illusory engine.

Mark,

A quick thank you for an absolutely fascinating CAM mag article about the Lohmann engine.

I was, by chance, reading the November 1952 (Motor Cycle Show) copy of The Motor Cycle and saw the Britax adverts for both the engines it was selling at that time, and having never heard of the Lohmann thought I would do an internet search. Your article resulted and I really enjoyed your combination of engineering knowledge, humour, and history. A model of how to write about a historical oddity.

So as well as saying ‘thank you’ may I also say ‘congratulations’?

Nigel Macdonald