Opening our article over 170 years ago may seem unlikely, but sometimes history can be stranger than fiction …

In 1854 the brothers Löb and Moses Simson bought a one third share of Alten Stahlhammer in Heinrichs, Germany (Heinrichs became a district of Suhl in 1936). Production of carbon steel began and the firm Simson & Co was founded in 1856, with the company beginning production of guns and gun barrels over the following years. In 1871 Simson installed its first steam engine at the factory to improve production capacity. Production of bicycles entered the programme in 1896, followed by the start of automobile production in 1907.

From 1914 Simson began building cars with four-cylinder engines as the 1.5 litre, 22bhp Model A, and 2.6 litre, 28bhp Model C, but suspended its car production in 1915, from when it spent the rest of World War 1 producing Mauser Gewehr 98 rifles for the German Army. Following the Armistice on 11 November 1918 and the subsequent Treaty of Versailles, Simson resumed car production in 1919 with a new four-cylinder range: the 1.6 litre, 22bhp Model Bo, 1.6 litre, 40bhp, 80km/h (50mph) Model Co, and 3.5 litre, 45bhp, 90km/h (56mph) Model D.

As a result of a post-war treaty to limit the recovery of the German arms industry, the reorganised Reichswehr was allowed to buy new handguns from only one company, so larger manufacturers such as DWM (Deutsche Waffen und Munitionsfabriken) were passed over in favour of Simson precisely because of its lower production capacity. Through the 1920s Simson manufactured .25ACP Westentaschenpistolen (‘vest pocket pistols’) for commercial sale and became the sole producer of military-contract Luger P08 pistols from 1925 to 1934, during which period it made about 12,000 Lugers. Simson was also responsible for repairing and refurbishing existing firearms for the Reichswehr, though DWM was also employed in this capacity, but in contravention of the Treaty of Versailles. In addition to making Lugers, Simson also repaired and refurbished Gewehr 98 and Karabiner 98b rifles, MG08 machine guns, and MP18 sub-machine guns.

In 1923 the Model D automobile was replaced by a 3.6 litre, 65bhp Model F as Simson’s first 100km/h (62mph) production model.

In 1924 the range of cars was completely revised under the Simson-Supra name made famous by successes of the Simson racing car. The first Supra-S and S-Sport models designed and hand-built by Paul Henze were technically advanced with four-cylinder, two litre, long-stroke, dohc engines. The S was rated at 50bhp for 120km/h (75mph) top speed, and the S-Sport rated at 60–80bhp for 140km/h (87mph). In 1925 a sohc Model So was introduced that produced 40bhp for 100km/h (62mph), and continued until 1929, while the S and S-Sport were discontinued in 1926.

Car models continued and, surprisingly, were joined in 1930 by the manufacture of prams!

1932 Simson Supra model A

Photo: Fahrzeugmuseum Suhl

In 1931 Simson introduced its first and only eight-cylinder, 4.7litre Supra model A of 90bhp for 120km/h (75mph), which was produced until 1934.

Under the Third Reich the factory was taken from the Jewish Simson family, and renamed several times while under Nazi, and later Communist, control.

Hitler’s government forced the Jewish Simson family to flee the country in 1936. Under the dispossession of Jewish industrialists (Aryanization), a trustee took control of the firm, and so by merger with other factories the Berlin Suhler Waffen- und Fahrzeugwerke (BSW) was formed. In the same year the factory produced its first BSW98 motor cycle, with 98cc engine and two-speed transmission. Critics of the Nazi government suggested a different meaning for the BSW initials: Bis Simson Wiederkommt (until Simson returns).

After the Simson brothers were exiled, weapons production at the Suhl factory was increased. From 1939 the company was called Gustloff-Werke–Waffenwerk Suhl, named after the assassinated Swiss Nazi Wilhelm Gustloff, and had subsidiaries such as the Otto Eberhardt Patronenfabrik (Otto Eberhardt Cartridge Factory). As well as the main works in Suhl, the Gustloff-Werke had branch factories at Griez in Thuringia and at Lódź in Nazi occupied Poland. Sachs-engined motor cycles up to 123cc were made within the Gustloff group from around 1934 until about 1940.

Gustloff-Werke products included anti-tank rifles, machine guns, gun carriages for anti-aircraft guns, and various calibres of small arms ammunition. The firm also continued to build bicycles, weapons, and cars until 1945.

In 1946, by order of the occupying Soviet Military Administration in Germany, the Gustloff manufacturing plant was partially dismantled and transported to the Soviet Union (USSR) as part of the Soviet reparations programme for damage inflicted on the USSR by Germany throughout World War II. In March 1947 the Suhl factory was integrated into the Soviet joint-stock Company Sowjetische Aktiensgesellschaft (SAG) Awtowelo (Soviet Autovelo Company Limited), along with BMW in Eisenach, Diamantwerke near Chemnitz (bicycles, motor cycles and knitting machines), Keilpart Toolwerke in Suhl, Rheinmetall in Sömmerda, Böhlitz-Ehrenberg ball bearing works in Leipzig, Ruhla watch and machine factory, and Fichtel & Sachs at Reichenbach.

On 1 July 1948 Industrieverband Fahrzeugbau (Industrial Association for Vehicle Construction) was formed to rationalise the manufacture of all sort of vehicles in East Germany under Soviet supervision.

IFA encompassed all East German vehicle manufacturers, Barkas (vans and trucks), EMW (cars & motor cycles), Framo (light lorries and vans), IWL (scooters), MZ (motor cycles), Multicar (light trucks and vans), Nordhausen (tractors), Robur (trucks), Sachsenring (Trabant), Simson (motor cycles), Wartburg (cars), other companies producing IFA W50/L60 branded trucks, model F8/F9 cars, Pitty, Wiesel, Berlin, and Troll scooters, and other manufacturers of vehicle related parts.

All IFA production was initially for export to the USSR, but control would subsequently be handed back to the German Democratic Republic (DDR) and, in 1952, the Suhl factory was renamed Volkseigener Betrieb Fahrzeug- und Gerätewerk Simson Suhl, with production of sporting guns, prams, and bicycles being slowly resumed, but the main focus returned again to building motor cycles.

Between 1949 and 1962 the Suhl factory produced over 209,000 single-cylinder, 250cc ohv four-stroke, four-speed motor cycles with shaft drive. The first 1,000 machines were built from July 1949 until December 1950, and all were exported to the USSR before the model was released to the DDR domestic market in 1951. The motor cycles were branded AWO until 1955, when the Simson name was revived. Some had Stoye sidecars fitted, and a Stoye Campi luggage trailer could also be attached.

Simson SR1

In 1955, the year that the Simson brand name was restored, and after over 100 years, the factory produced its first moped. The first model was the two-stroke 48cc SR1 rated at 1.5bhp, succeeded by the SR2 in 1957, the later SR2E version rated at 1.8bhp, and the KR50 48cc ‘Schwalbe’ scooterette in 1958.

When four-stroke motor cycle production ended in 1962, the Simson factory was directed to concentrate on moped production.

In 1964 the original 38 × 42mm, long-stroke, 47.6cc engine design was revised to slightly over-square dimensions of 40mm bore × 39.5mm stroke, now 49.6cc displacement, and launched the SR 4-1 Spatz and SR 4-2 Star 50cc mokick motor cycles.

Moped production had grown steadily in Suhl, building up to 200,000 mopeds per year, and by 1965 the factory employed 4,000 workers.

In 1966 Simson introduced the SR4-3 Sperber, with the same 50cc engine but with power increased to 4.6bhp and more angular styling than the Spatz and Star.

In 1968 Simson was merged with VEB Ernst-Thälmann-Werk Suhl to form the VEB Fahrzeug- und Jagdwaffenwerk Ernst Thälmann Suhl, while popularity of the new Schwalbe Scooterette helped to promote the Simson company as the DDR regime propaganda seized the opportunity to publicise the scooter as a success of East German two-wheeler motor manufacturing. The Schwalbe continued to be developed over the years, but more as a result of Simson design and development than opportunistic efforts of the powers to be.

Spatz production was ended in 1970 as Simson introduced a bicycle-style, pedal-start 50cc, 1.6bhp SL1 Mofa. The model was revised as the SL1S in 1971, but discontinued in 1972.

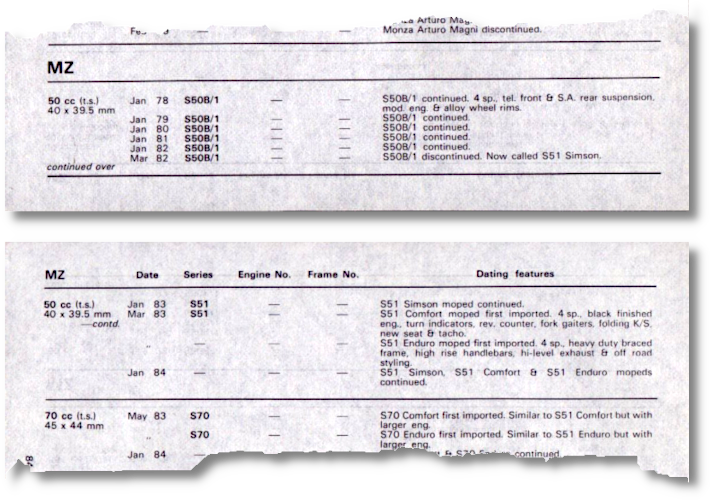

Star production finished in 1975, at which Simson revised its image with a new S50 series. This employed the 40 × 39.5mm, 49.6cc engine at 9:1 compression, 19mm carb, rated at 3.6bhp @ 5,500rpm and quoted at 37mph. The S50 was launched with two new three-speed models: the basic S50N with no bells or whistles and moped type mag-flywheel ignition, and the S50B with battery supported electrics and indicators. The S50B was replaced by an up-rated S50B1 model in 1976, and an S50B2 with electronic ignition. The S50 series ceased manufacture in 1980, though S50B1 models remained on sale in the UK until notified as discontinued in March 1982.

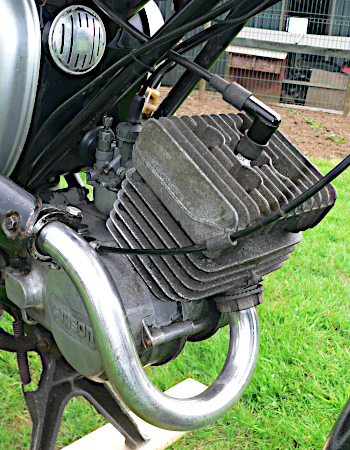

The S50’s successor was the S51, for which Simson revised the styling again and fitted a new long-stroke IFA-branded four-speed all-alloy engine, with 38mm bore × 44mm stroke for 49.9cc, 9:1 compression, 16mm carburettor, and rated at 3.7bhp @ 5,500rpm.

Glass’s Index lists the S51 taking over UK sales in March 1982 but doesn’t qualify which version this was.

Since we know of a UK-registered 1982 S51B1-3 model, we presume that this was the unspecified type, and here is how to identify the respective models:

| S51N | Basic model, moped type mag-flywheel ignition, stop button on handlebar, no battery, no indicators, plain suspension units, three-speed engine. | |

| S51B | All models had battery ignition with key switch, and indicators, plain suspension units. | |

| S51B1-3 | had three-speed engine (indicated by ‘3’ cast onto the clutch cover + IFA logo) | |

| S51B1-4 | had four-speed engine (indicated by ‘4’ cast onto the clutch cover + IFA logo) | |

| S51B2-4 | further had electronic ignition, 35/35W headlamp, and larger 100km/h speedometer. | |

| S51E (Enduro) | four-speed with high-level exhaust, and knobbly tyres. | |

| S51C (Confort) | Top of range/most expensive model, roadster with long seat, all features, adjustable rear shocks, side stand, rev counter, fitted mirrors. |

50cc S51C Confort and S51E Enduro were added to UK imports in March 1983, with 70cc S70 Confort and 70cc S70 Enduro added in May 1983.

Our featured Simson is a S51E Enduro 1983 registered model, as the first year of its introduction in the UK. The Enduro is mainly characterised by its high-level exhaust system and knobbly tyres, but there are also more subtle distinguishing changes from the other ‘road’ models. The high-level exhaust requires a modified right-hand toolbox cover, has slightly shorter mudguards, higher handlebars, Enduro struts bolted into the frame to support the lower headstock, adjustable rear shocks, a folding kick-start, longer saddle, and silver finish option.

The headstock frame plate indicates 85kg, and the Simson brochure similarly gives the weight as 84kg—over 13 stone for a moped? Really?

It looks a bulky and heavy bike, but surely not that heavy, so out with the scales, and 30kg front and 43kg rear! That’s 12kg lighter, nearly 2 stone! A 15% misread is hardly some minor weighing error!

The ‘MZ’ frame plate is in English, and apparently fitted by the MZ importer Wilf Green, so registered as an MZ instead of Simson, which seems to have been a common misnomer, and it is also indicated as 30mph restricted moped.

Despite being presented as a performance-limited moped with a kick-start and footrests, the Simson looks every bit like a physically large sports motor cycle, which would likely be more comfortable for taller and larger riders than many of the typical oriental mini-scooters of the period. It also has a really long seat, and you could probably sit three people on it!

It’s certainly big and chunky, with lots of cast aluminium: 120mm brakes in finned alloy hubs, with alloy brake plates, and a rod operated rear brake that unusually has a brake-light switch built into the rear brake plate, though not one on the front brake plate. The wheels are built with no-brand alloy rims, shod with 2.75 × 16 tyres, and the front and rear wheels are interchangeable, so if you have a puncture in the front, you can switch the wheels round to have the puncture in the back instead, so that seems useful… The aluminium ware continues as cast alloy fork sliders and a cast alloy stand.

The swing-arm works with conventional 360mm twin-shock rear suspension, exposed springs with adjustable pressure settings, and a fully enclosed chain running through rubber tubes and connecting the rear chain guard in the MZ style.

A flat key works in an ignition lock in the left-hand toolbox, with a four position switch marked in the cover panel 0 = off, 1 = ignition, II = Lights, 3 = Park (so you can leave the lights on with the key removed).

Fuel tap off–on–reserve is situated at the bottom left-hand side of the tank, and switch on to fill the 16mm BVF carburettor. Turn the ignition switch in the left-hand side panel to 1 (on), and there’s a choke trigger on the throttle ‘Start→’.

The kick-start is situated on the left-hand side of the engine, which is typically an eastern European feature that is unnatural and awkward for most riders to operate while sitting on the bike, so generally the favoured process is to stand off the bike to be able to kick-start with the right leg. Not so useful if you happen to stall in traffic.

A couple of stand off jabs at the kick-start soon has it running, and we give it a couple of minutes idling to warm, then pull in the clutch with four-speed gears, one-down/three-up.

Take-off in first is capable enough, then readily into second, then third, but it’s fair to say already that acceleration is soft and unspectacular, then fourth is very much a case of waiting for the speed to build up. It’s about what you’d expect from a large and heavy sports-style ‘sloped’ with a 38mm bore × 44mm long-stroke motor of 9:1 compression. The engine was designed for useful torque at low and medium speeds, but proves less effective at higher revs.

The 60mph ‘no brand’ speedometer, with a red indicator lamp sited above the 30 marker, seems to read a little slow, showing 35 along the flat, which our sat-nav paced at 37.

It definitely didn’t seem restricted to 30mph as the ‘sloped’ plate might lead you to believe, but probably not that much quicker for anyone to be concerned. Perhaps on a downhill run you might see a little more, but the Simson is more a steady plodder rather than a sports machine.

Noting indicators were only present on the back of our bike, it seems the front ones had been removed.

In 1983 Simson introduced a 70cc S70 model which employed the S51’s long-stroke engine bored out by 7mm, giving over-square dimensions of 45 × 44 mm and producing 5.6 bhp.

After 18 years, production of the Schwalbe scooter was ended in 1986 in favour of the continuing manufacture of the more modern Simson 50cc moped models.

The Fall of the Berlin Wall on the historic day of 9 November 1989 signalled the beginning of the end of 44 years of Soviet influence on the country. Lack of investment, and the general obsolescence of industrial plant and products would soon start compromising the prospects of many of the IFA manufacturers. The S51 was built in various forms until production ended in 1990.

In 1990 the S51 and S70 models were revised as the 50cc S53 and 70cc S83, which were offered in a range of on-road and off-road versions, but total production of all versions from 1990 until 1994 only amounted to around 10,500 machines.

Wartburg and Trabant production was closed in 1991.

In 1992 Simson resumed tricycle production with a 50cc × 3.3bhp model, the SD50LT, based on the SR50 scooter but with a single seat and a 360-litre cargo space behind it. From 1994 the model was named the Albatros, and production continued until 2002.

In 1993 the Suhl factory began making the Hotzenblitz electric car under contract for Hotzenblitz Mobile GmbH & Co. KG of Ibach in Baden-Würtemberg. The car had only had two seats and weighed 780 kg, rated at only 16bhp with a range of only 100-150km, and was basically a complete failure. Only 140 examples were built by the time production ended in 1996.

In 1993 the SR50 and SR80 scooters were revived, but by 1997 the renewed production of the SR series totalled mere 3,100 examples and, despite the low uptake, production struggled on until 2002.

In 1994 the S53 and S83 were revised with two versions each: the road-going Alpha and off-road Beta. These were made until 1996 but production figures are unavailable. In 1996 Simson began reverting to names of nostalgic historical success in an effort to revive flagging sales, but had already lost its export markets. It revived the Star model name for a new 50cc scooter with more voluptuous and fully enclosed bodywork, production of which would continue until 2001.

In 1996 Simson renamed the Alpha and Beta range by reviving the Habicht model name. In 1997 it introduced a 5.1bhp version of the 50cc machine, for which it revived the Sperber model name. In 1999 new 50cc models were introduced: the Sperber Sport with a sports full fairing and a new Spatz model with a space frame. Further 50cc models were the semi-off-road Fighter in 2000 along with the SC and TS series in 2002.

In 1998 Simson had introduced a Shikra 125cc model. This featured a space frame and was powered by a Honda four-stroke 15bhp engine built under licence in Taiwan. In 2000 the Shikra name was discontinued, power output was reduced to 13.6bhp and the model was re-branded as the Simson 125.

Several investors tried to keep Simson production going and bring new developments to market, but production ceased in autumn 2002.

On 1 February 2003 Simson bankruptcy proceedings were held, in the wake of which the remaining 90 employees were made redundant without any compensation.

MZ closed in 2008.