The Worme in 2015

The Legend of the Worme began around 2015 when this strange and ancient beast first turned up at Lord Thurlow Village Hall at Great Ashfield, for the 33rd East Anglian Run.

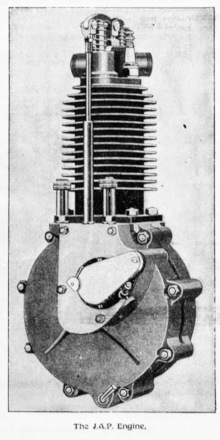

In its original and simple form it’s possible maybe to recognise the power unit mounted on the front of a Batavus ‘Splendid’ ladies cycle: it’s a JAP Model-O industrial engine, but we didn’t know that JAP made a version of this engine as a cyclemotor?

Here’s one story that we never thought we’d ever be doing about a cyclemotor…

John Alfred Prestwich (1874–1952) was an English engineer and inventor. In his early twenties he founded J A Prestwich Industries Ltd in 1895 and was a pioneer in the early development of cinematography projectors and cameras, working with S Z de Ferranti and, later, with the cinema pioneer William Friese-Greene.

1901 JAP engine

In 1901 Prestwich designed and built his first motor, an OHV four-stroke clip-on 293cc engine of 70mm bore × 76mm stroke for attachment to the front down tube of a bicycle-type frame. It had an atmospheric inlet valve, was rated at 2.2hp @ 1,600rpm, and went into limited production in 1902.

In 1903 the first complete JAP-engined motor cycle was shown at the Stanley Show, among a number of other names which you may (or may not) recognise: Abingdon, Aurora, Binks, Bradbury, Campion, Clark–Cluley & Co, Clyde Cycle & Motor Co, Crypto, Elswick, Humber, Kerry, Minerva, Oxford Autos (showing Morris motor cycles), Princeps, and Triumph Cycle Co with a Belgian Minerva engine.

The J A Prestwich motor cycle engine was built into a BSA frame with sprung forks and a vertically mounted 473cc , 3.5hp OHV engine. A single push-rod opened both valves, which the cam action tracked to pull and push as required. JAP also displayed a lightweight model with its 2.25hp engine fitted at an inclined angle.

From the development and display of this first practical British produced, mechanically operated, overhead valve engine by JAP, Triumph adopted the motor to produce complete motor cycles from 1903, while JAP continued with its own further 2.5hp and 3.5hp complete motor cycles into 1905, as well as a three-wheeler.

In 1906 JAP added a 6hp V-twin, and a fore-car fitted with an 8hp three-cylinder in-line engine, but just two years later John decided to stop building his own complete motor cycles in order to concentrate on the manufacture of proprietary motors instead. JAP engines quickly became extensively adopted in various cyclecars over the 1910 to 1914 period when they were popular with small manufacturers. In 1914 JAP announced a new engine made specifically for the cyclecar: a V-twin of 90mm bore and 85mm stroke (1082cc ). The engine had a larger flywheel than the motor cycle engine, and an enclosed magneto drive, for fitment to a Morgan three-wheeler. 1914 also brought about the First World War, so JAP switched over to repair and overhaul of aircraft engines for the Royal Flying Corps, and munitions manufacture.

In 1919 John Prestwich was asked by a pencil manufacturer to design a machine for painting mass produced pencils, and created one half the size of machines currently in use and capable of a greatly increased output. When the pencil manufacturer went bankrupt in 1920, John purchased the business, and set up Pencils Limited to exploit his invention of new machinery, and the company started making Master Pencils, also at the Northumberland Park site in Tottenham, London.

JAP engines became widely used in many famous motor cycle marques, including Brough Superior, AJS, Triumph, Zenith, HRD, with many more in the UK and other continental customers. Engines were also supplied for early aircraft, chainsaws, agricultural cultivators, and light rail maintenance trucks.

Following the impact of the Great Depression and motor cycle manufacturers increasingly resorting to making their own engines instead of buying in proprietary motors, JAP motor cycle engine sales steadily reduced, and production increasingly shifted toward small industrial and agricultural engines. During World War 2, Prestwich returned to munitions production, making portable generators powered by JAP stationary engines, building around 240,000 industrial petrol engines in support of the war effort, along with making millions of aircraft parts, fuses, etc.

On 23rd April 1951 J A Prestwich Industries Limited was formed to incorporate the assets of J A Prestwich and Co Ltd and Pencils Ltd, which was now producing 1.5million Master Pencils a week, and was the largest pencil maker in Europe. Nominated directors were John Alfred Prestwich: Chairman and Managing Director, John Edgar Vincent Jobson, Edward Stuart Prestwich, Douglas Percival Prestwich, Gerald Winfrid Stanfield Bagshawe, and Percy Gyllenship Langford, with William Dodsworth Hine as Works Manager.

Soon after incorporation of the new company, the business was floated on the London Stock Exchange to raise money for new production of small utility engines under the JAP name for both stationary and motorised equipment in a variety of applications. They ranged in size from the smallest Model-O two-stroke engine to the much larger type-6 four-stroke engines, and were used on rotavators, generating sets, milking sets, water pumps, lawnmowers, hay elevators and other agricultural machinery.

Some four-stroke and two-stroke motor cycle engines continued to be listed for low-volume manufacturer AJW for the 500cc Flying Fox & Speed Fox and the 125 Fox Cub of 1953 (which failed to go into production and the three-speed motor was subsequently de-listed by JAP after nobody bought it), and the Hercules Grey Wolf & Her-Cu-Motor mopeds 1955–58.

Most post-war industrial engines were four-stroke, but there were some two-stroke engines such as the Model-O, so what was it?

JAP Model-O Type 28 two-stroke, 35mm bore × 35mm stroke = 34cc and rated at ⅓hp @ 2,500–3,500rpm with Amal 380 Carb and strangler filter. Instead of using a conventional ‘open’ exhaust port, the cast iron cylinder unusually has its exhaust gases vented through lines of small drilled holes into the manifold. You’d probably imagine that this might compromise spent gas scavenging, but the iron cylinder is fitted with an aluminium deflector-top piston, which delivers efficient gas exchange at lower revs through the single transfer port at the back of cylinder. At higher revs the effectiveness of deflector scavenging tends to become more compromised than Schnürle loop port scavenging.

Another aspect of the unconventional Model-O exhaust port arrangement is it dispenses with the need to fit ring pegs in the piston, since the rings may safely rotate without a ring end going into a port, and un-slotted pistons and rings are cheaper to make. The cylinder is topped with a cast alloy head.

Despite being a low cost industrial proprietary motor, JAP knew how to make better and more durable engines, and, unlike some of the budget-built cyclemotors of the 1950s (yes, Cymota & GYS, we could be looking at you), the Model-O was a sound construction. The JAP un-caged roller big-end bearing is a way better design than a plain-bush big-end which requires a heavy oil mix to maintain effective lubrication. The JAP engine also has a proper two-journal crank instead of cheaper plain bearing overhung crank designs, and this O-engine has also had a conversion from single-row to double-row main bearings for further axial support.

It has a Wipac Migemag 1-1263 magneto with a fan-cooled flywheel, which is based on a Series-90 mag-set but without any lighting coil, so the cycle lights are driven by a friction dynamo running on the rear tyre. Total motor weight was given by JAP as 11½lbs.

Worme gained its name as an anagram of Mower since it uses an ex-lawnmower engine, which would have been a cylinder mower because this requires less power than a rotary mower. Being a chain drive machine, it would have been fitted with a drive sprocket, while conversion to a roller-drive cyclemotor would require something that JAP never made. The drive roller was home-engineered from a hardened steel Burman gearbox pinion, which is very durable though prone to slip in the wet, so can require more pressure on the tyre to maintain the drive when it rains.

This JAP O motor has evolved since its first iteration, particularly to address issues of the engine running too hot since it was earlier relying on simple airflow for cooling. Now it’s fitted with extra steel ring extensions brazed to the meagre original cylinder fins, and a polished brass fan shroud fabricated and screwed together to direct fan air from the flywheel across the cylinder to improve cooling—which looks totally steam-punk!

The cylindrical tank is the original ½-litre JAP fuel tank, and roller-drive cyclemotors tend to be quite thirsty on fuel, so it might be necessary to carry an additional reserve if any longer riding distance is being considered.

So: fuel on, choke on, and since there’s no decompressor on the Model-O, the most effective way to start is to pedal the bike up to speed, pull the clutch lever onto latch and keep pedalling to get the motor turning and maybe just tease the lever throttle lever to get it to fire. Once running, the clutch can be unlatched to ‘neutral’, then ease back the choke as the engine warms to settle.

The clutch lever has reversed operation, so the lever ‘pulls on’ the drive, and a return spring pulls off the drive when the grip-lock lever is released. If the tyre still slips when it’s wet and you’re going uphill, you can pull on the clutch lever a bit more beyond the latch to get extra grip.

With the engine now running, pedal away then pull the clutch lever to latch, and open the throttle lever. Generally the throttle lever is going to be set full on because a 60–70 year old 34cc motor is only going to run along at cycling speed, way slower than town traffic. You mostly only throttle back to judge junctions and motorists will usually relate to cyclemotors today as bicycles or E-bikes, so it’s generally not much of an issue.

Road conditions were wet on the day of our test, so roller pressure was adjusted to ‘firm’ to reduce the tendency of drive slip, which increases friction and will expectedly compromise the top speed slightly. Worme paces around 20mph on the flat and 22–23mph on a light downhill run though under dry conditions with the roller-drive pressure backed off to minimum setting, as much as 24mph can reportedly be achieved!

The engine ran surprisingly smoothly, with little vibration, and mostly clean two-stroke firing, with the only four-stroking occurring when choked or cold running.

The 26×1⅜ wheels & tyres gave a hard ride on poor surfaces, and crossing speed bumps conveyed such a jolt that you quickly learned to slow down for them. The modern Sturmey–Archer three-speed coaster hub offered useful cycling assistance when a boost was required, and the back-pedal brake could still contribute some braking effort since the speed was low. Front braking is by a cable to a rod stirrup arrangement.

By 1957 practically all shares in the JAP company had been acquired by the Villiers Engineering Company Limited of Wolverhampton, giving them control of their former competitor, at which the two remaining JAP directors resigned, and final links with the Prestwich family were severed on 17 September 1957. JAP industrial and speedway engine manufacture and Master Pencils continued under Villiers into 1961 but, in 1962, engine manufacture moved from Tottenham to Wolverhampton leaving the Northumberland Park site to sub-contract engineering works. In September 1963 the Tottenham works were closed causing 430 redundancies.

J A Prestwich Industries Limited was liquidated in 1964 at just about the same time as Villiers itself was in the process of being taken over by Manganese Bronze Holdings.

Surprisingly JAP never produced any cycle/engine kits during the cyclemotor boom in the early 1950s.