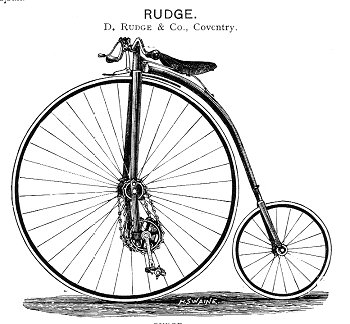

Wolverhampton 1868, and our trail starts from obscurity in a small workshop behind the Tiger's Head Inn, where the innkeeper, Daniel Rudge, began building velocipedes - forerunners of the bicycle. Within a few years he registered patents on ball-bearing wheel spindles and adjustable cycle pedals, going on to build up quite a considerable business before his death in 1880. The business was transferred from Dan's widow, to George Woodcock, a shrewd Coventry lawyer who already held interests in Smith and Starley (manufacturers of Ariel Cycles and Europa sewing machines), and Haynes & Jeffries. Woodcock merged all three companies under the clumsy title of "D Rudge and Company and the Coventry Tricycle Company".

D Rudge and Company

'Safety' bicycle, 1885

The sewing machine operations of Smith and Starley were housed in modest premises addressed Trafalgar Works at Crow Lane, Coventry, and adopted by Woodcock as headquarters for the new combined enterprise. From 1885, Woodcock and a few of his friends had launched a private limited liability company under the title of "D Rudge and Company Ltd" and, over the following years, the buildings were extended, demolished, and rebuilt again in step with the expansion of production. George Woodcock died following a short illness, the home cycle market showed signs of saturation, and the once-lucrative American trade dwindled away with the establishment of the USA's own cycle industry. Without his guiding hand on the tiller, the business was headed for the rocks in the early 1890s.

Charles Henry Pugh

A few miles north, and based at Whitworth Works, Rea Street South, Birmingham, Charles H Pugh Ltd had developed from manufacturers of screws and ironmongers' sundries, into suppliers of bicycle fittings and stampings to other trade manufacturers.

In 1891, Pugh was preparing to enter its own bicycle manufacture by forming The Whitworth Cycle Company with Charles Vernon Pugh as Managing Director and John Vernon Pugh as Works Manager. Requiring a trademark, the new Whitworth bicycles adopted the device of an open red hand superimposed upon a bicycle wheel, registered to Charles Henry Pugh of Birmingham - screw and velocipede manufacturer.

As Whitworth Cycle's business flourished and converted to a limited company in 1893, the requirement for larger premises was becoming more pressing. Talks were entered into with the ailing Rudge Cycle Company, resulting in the formation of Rudge-Whitworth Ltd in October 1894. Though the headquarters of the new company were registered back at Crow Lane in Coventry, the reins of the business were very firmly held in the grasp of the Pugh family, while the original Charles H Pugh Ltd business continued from Whitworth Works as a supplier of parts and sub-assemblies to Rudge-Whitworth and as manufacturer of other trade components.

Rudge's first involvement with motor cycles came about as Charles Vernon Pugh entered an arrangement with Werner of Paris, to market Werner motor cycles in South Africa through the Rudge-Whitworth distribution network based at Johannesburg. It was not until mid-1910 that the Coventry works began work on an experimental machine of their own design, and the first production Rudge motor cycle appeared in 1911, during which year John Vernon Pugh evolved the famous Rudge Multi gear, and Charles H Pugh Ltd had patented a new Senspray carburettor that became standard fitment for Rudge machines thereon.

In 1914 the Rudge Multi of Cyril Pullin claimed victory at the Isle of Man Senior TT, after which, motor cycle production was set aside as the works became occupied with military contracts.

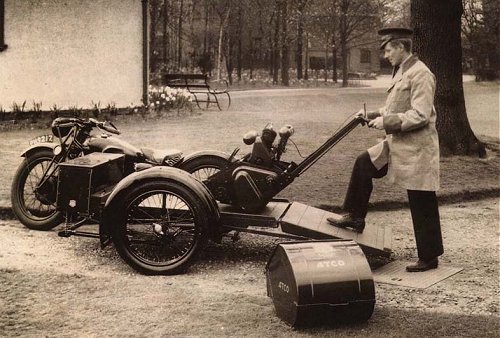

Unloading an Atco motor mower

from a Rudge motor cycle combination

Returning after the Great War, a 998cc V-twin Rudge was introduced in 1919, John Pugh began work on a new 3-speed gearbox and, back at the Whitworth Works, another great invention was about to be created.

Historically, small lawnmowers had been human propelled or, in the case of larger cutting units, pulled by a donkey with padded hooves, so as not to damage the lawn. The story goes that the world's first petrol-powered lawnmower was pioneered in 1921 as a request to Charles H Pugh of Birmingham from Mr Bull, Managing Director of the Atlas Chain Company, another business within the group, to install a petrol engine to a lawn cutter following the death of his donkey. As a derivative from the Atlas Company, the machine was called the "Atco".

Seeing potential in the invention, Pugh's built 900 × 22-inch cut self-propelled mowers in the same year but the distribution trade failed to see any prospect for the new device and it was left to the company to sell their £75 Atco's individually by salesmen travelling the country using Rudge motor cycle combinations to transport mowers on specially adapted flat-bed sidecars.

Trading arrangements between the Rudge and Whitworth Works lasted well into the 1920s, by which time the Birmingham branch had become mainly concerned with making Atco motor mowers, and the two businesses became wholly independent.

John Vernon Pugh remained with Rudge through its period of racing successes of the late '20s to early '30s, into the Great Depression with the company's financial troubles toward the mid-'30s, until his death in 1936, whereupon the business passed to The Gramophone Company Ltd, manufacturers of radio equipment and records under the HMV trade-mark.

Management of the Whitworth Works passed from Charles Vernon Pugh to his son, John Geoffrey Pugh and the business was set for another unexpected twist!

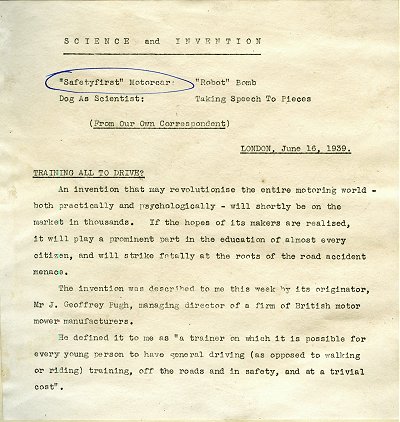

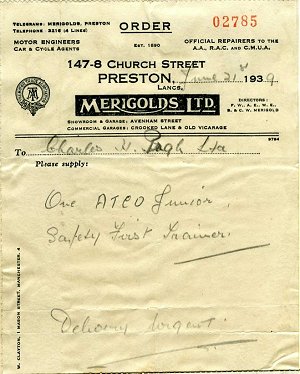

16 June 1939

Press release for the Atco Trainer

Quoting the Alness report on road safety for the Lords Select Committee on Road Accidents, "One of the most important remedial measures lies in the education of children, and that instruction in road safety should form part of the school curriculum".

These may have been some of the thoughts that led John Geoffrey Pugh to start development in 1938, and issue invitations on behalf of The Chairman and Directors to a press luncheon at Grosvenor House Hotel, Park Lane, W1 on Thursday 22nd June 1939 - the occasion being to formally announce the launch of the Atco Junior Safety-first Trainer.

This machine created so much interest at the time that, over the following months, articles about it appeared in practically every periodical and journal from Lands End to John o'Groats, and beyond - even as far afield as the French L'Argus de l'Automobile!

Supported by a series of advertisements posted in publications from The Times to The Tattler, from the Meccano Magazine to Punch, the manufacturer was Charles H Pugh Ltd of Whitworth Works, Birmingham, none other than maker of the famous Atco lawnmower!

Lord Alness himself, as Chairman of the House of Lords Select Committee on the Prevention of Road Accidents, several members and MPs inspected the vehicle for themselves at Grosvenor House on 22nd June 1939, and gave their blessing.

a day before the official launch

the first order comes in...

"Delivery Urgent"

So what was this machine to create such widespread interest?

The Atco Junior Safety-first Trainer was a miniature motorcar! Described for boys and girls from 7 - 17 years, the specification featured a 1hp 98cc 2-stroke Atco-Villiers rear mounted engine, and reproduced the controls of a full-sized car with accelerator, brake and clutch pedals in the normal positions. Single forward and reverse gears are driven through a cone clutch, by chain transmission, and top speed was given as 8 - 10mph. The Trainer rode on disc wheels with pneumatic Dunlop 16×2½ tyres and was accompanied by a 68 page illustrated training manual. Cost was posted at £35, and available to local authorities and schools at 'special rates'. An HP scheme was also offered with a deposit of £8-15s, and 12 monthly instalments of £2-7s.

Distribution of the mini-car was to be through the motor trade and established factors of the Atco motor mower.

Further details would lead us to expect a pull starter handle centrally between the seats, and single brake on the rear axle, controlled primarily by the foot pedal, but also actuated outside the bodywork by a right hand lever.

At the Atco works in Birmingham, a special demonstration track was laid down, complete with Belisha beacon crossings.

By 5th August 1939, further illustrated notes featuring two trainers began appearing in the national dailies, on the production of a road 'Safety-first' educational film for showing in schools, being shot at Northern Polytechnic, Holloway Road, London.

Filming Atco Trainers at Northern Polytechnic, 4 August 1939

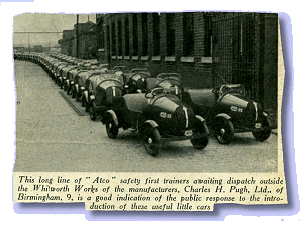

On 1st September 1939, the Hardware Trade Journal pictured a "Long line of 'Atco' Safety-first Trainers awaiting dispatch outside the Whitworth Works", and Everywoman's magazine ran a seasonal term school-starters feature, including a section on the 'Trainer'.

This was however the last idyllic day of summer, as peals of thunder echoed through the early morning mist in Danzig's Neufahrwasser Harbour at 4:45am as the battleship Schleswig-Holstien hammered the Westerplatte fortress in the opening broadside of a dark storm that would rumble across Europe.

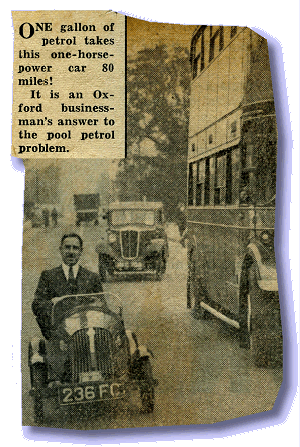

Despite the outbreak of war, the little car still showed it had some unlikely cards to play with the introduction of rationing and pool petrol. An Oxford businessman was pictured in the Sunday Chronicle of 26th November 1939, driving a road registered Trainer in city traffic!

The troubles exploded onto the world stage at Pearl Harbour on 7th December 1941, and though people's minds largely became occupied with other issues, the cheery little car still kept popping up. During the height of the war, two Trainers were pictured in the Bournemouth Daily Echo of 17th June 1943 as demonstrators promoting Bournemouth's Safety Week!

1939 - 45. Over the duration, 100,000sqft of factory space at Whitworth Works was given over to munitions production, which contribution to the war effort was highly commended by the ministries concerned. With the cessation of European hostilities on 9th May 1945 and with the Pacific situation moving toward conclusion aboard the battleship USS Missouri anchored in Tokyo Bay on Sunday 2nd September 1945; after 6 years and 1 day, the World War that started on a battleship, ended on a battleship, and Britain was beginning to pick up pieces of its earlier life postponed by the conflict.

The Atco Trainer re-appeared in a feature by the Daily Mirror in May 1946 as a promotion for a road safety scheme by the Royal Society for the Prevention of Accidents, and again as a prelude to a 1948 Safety Exhibition at Hackney Town Hall, which was opened by L J 'Jim' Callaghan MP, Parliamentary Secretary to the Ministry of Transport, as two twelve-year-olds demonstrated an Atco Trainer for the press.

An Atco Trainer posed with a Model O Bedford and a

Police Wolseley 18 for Hackney's 1948 Safety Exhibition

Thereafter, references to the Atco Trainer appeared to dry up, and the little car faded into the obscurity of time...

Our featured Atco Trainer is currently a museum display exhibit and appears not to have been run for some time. It takes rather a bit of fettling to return the machine to functionality, cleaning points and re-timing to restore the spark, flushing out the carburettor and petrol tank, fresh fuel, a couple of failed attempts, then making up a new throttle cable, and we're ready to try again.

To start the Trainer, lift the rear bonnet and turn on the fuel tap (the tank is a period Atco lawnmower 'torpedo' tank across the front of the engine compartment). You'd normally lift out the seat base to pull the start lever but, since we'd had a couple of failed attempts flooding the plug on choke, we left the choke off, just gave the car a push, tweaked open the throttle - and it went straight away! Adjust up the throttle cable, and within a minute the engine is happily ticking over like it's run every week, then, after discovering that forward gear requires holding in with your right foot on the lever to prevent it kicking out, we're zooming round the backyard circuit of Ipswich Transport Museum. With the fan-cooled engine running, the rear bonnet is set slightly open to provide cylinder ventilation. The 'old-style' throttle operates by a lever on the steering column, which you have to hold open with your right hand. Once you've got under way with just the single forward gear, you don't need to use the clutch anymore until you require to stop and select neutral again, and since the motor proves so flexible in its single drive ratio, you also find you don't even really need to use the brake. For such a little car, the steering proves surprisingly heavy to wrestle through a turn, and on the return leg coming on the downhill section of a circuit of the yard, the photographer requires a brisk running pace to pan with the action, so the given top speed up to 10mph seems pretty fair.

The turning circle proves unexpectedly large for the scale of the car, but undoubtedly contributes to its confident stability in all manoeuvres at any speed. There's plenty of noise from Trainer's 2-stroke engine with its roaring fantail exhaust, open transmission gears, flailing chaindrive, wooden floorboards and resonating panels, so you feel every bit that you're driving a 70 year old vintage go-cart. It's pretty tricky for an adult, particularly trying to thread their right leg down to work the footbrake, but child's play for any youngster, and easy to appreciate the magic of the Trainer experience to one of that age.

Business boomed as domestic mower production resumed when peace returned, and the Birmingham sites had increased four-fold by 1950.

In 1959/60, Charles H Pugh Ltd, Birmingham performed a company review to assess prospects of reviving the Trainer project. The historical report shows "The original programme planned for 1,000 Atco Trainers in batches. About 200/250 (the first batch), were produced before war broke out. Altogether some 200 were sold and the remaining stock and components written off" (being recycled into the war effort in the same fashion as garden railings and surplus pots and pans). The company reported that, "Ever since, we have had rare enquiries and occasional calls for spare parts and branch overhaul".

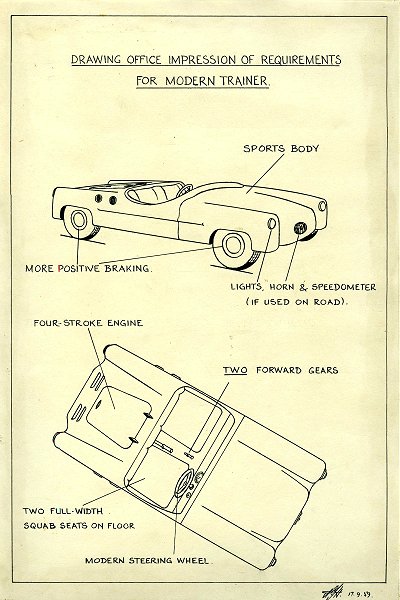

Idea for a Modern Trainer, 1959

The following "Review of possibilities in regard to commercial chances of a modern edition of our 1939 Trainer", reported "The main feeling emerging from talks has been that to do any good today and at a price of say £150 or more, a Trainer would have to be fitted out so near to the modern bubble-car that there would be little difference between the two articles. The reasoning seems to be that the specificational appeal should enable it to qualify - whenever wanted - for a road licence. Some of the mechanical refinements (compared with the 1939 model) are to a certain extent indicated on the attached sketch which the drawing office has made of an imaginary 1959/60 model".

The Trainer revival project was not recommended and progressed no further.

1965 - Charles H Pugh Ltd and the Atco brand became part of the Qualcast Group.

1975 - Atco lawnmower production moved from the West Midlands to the Stowmarket site of Suffolk Iron Foundry, with the Birmingham location becoming the Qualcast Group spare parts centre Serpar.

In the early hours of November 5th 1981, a fire ripped through the buildings of the Charles H Pugh premises, destroying the old Whitworth Works with its entire stock, resulting in a complete closure and transfer of all business to East Anglia.

1995 - Robert Bosch Gmbh acquired Atco-Qualcast Ltd and prestige Atco branded mowers continue in production under the auspices of Bosch Lawn & Garden, who most kindly supported production of this article, provided archive material, and assisted with the research.

The Atco Trainer featured in this article, was graciously loaned by Richard Brockbank & family, and can currently be seen on display at Ipswich Transport Museum.

For further reference, IceniCAM Information Service holds over 40 related text and picture file records on the Atco Trainer.

Next - our second support feature for Iceni CAM number 8 is the first of three chapters, eventually leading back up the path to the compost pile at the top of the garden - though maybe just an excuse to reveal a couple of unlisted cyclemotors along the way!

This article appeared in the October 2008 Iceni CAM

Magazine.

[Text & photos © 2008

M Daniels. Period documents and pictures from IceniCAM Information Service, Ipswich Transport

Museum and Atco Lawnmowers]

The Atco Trainer

at 'speed'

When the little Atco microcar turned up on loan to Ipswich Transport Museum, we knew right away that we just had to produce an article on it, setting the project in motion during June 2007, and collating a working research file to commence drafting the text while out in Mauritius over Easter 2008. With permission to run the car for test, and feature it on the EACC/IceniCAM stand at Copdock Show, it was full steam ahead to complete the article for the Iceni 7 publication at this event. Since no-one seemed to have previously produced an article on the Atco Trainer, there was keen interest from other publications for franchised versions (Priory Press & RUMCar magazine), and the article grew to a two-chapter option with the 'Whitworth Threads' prequel added to extend appeal to The Radial magazine - then everybody was interested in taking the full version!

Another press cutting:

1939 shop window display

in Guildford

The Trainer hadn't been run for rather some time, so took quite a bit of fettling before we were whirling it round our little test circuit in the backyard of the Transport Museum, while Becky came along to model the photoshoot and add a bit of contemporary glamour. Though the Trainer was something of a diversion from our usual bikey stuff, we felt our general 'low powered vehicle' brief allowed a bit of artistic licence. It certainly made an entertaining tale and feedback from our readers has been really great - so it looks as if we got away with it! Many thanks to Richard Brockbank and family for permission to run and feature the car, Roger Tombs at Bosch Lawn and Garden for providing archive material, assistance with research and production, and arranging sponsorship of the article, and Ipswich Transport Museum for access and use of their premises.

When working through the research file on the Atco Trainer for drafting up the text, there was so much wonderful original material that we would have loved to accompany the feature - but it was obvious there was never going to be enough space in the printed magazine, meaning more hard editorial decisions for IceniCAM 7. For the second time in the same edition, our article was specifically written for the Director's Cut website version. Not only do we have a massive Director's Cut, but also a seperate page dedicated to the the Atco Trainer's launch party.